Heat Exchangers for CCS/CCUS and CO₂ Compression

Heat Exchangers for CCS/CCUS and CO₂ Compression

Across Europe, CCS/CCUS (Carbon Capture, Utilization and Storage) projects are accelerating. In these systems, pressure and temperature control are critical—especially in the CO₂ compression section and during conditioning for pipeline transport and injection.

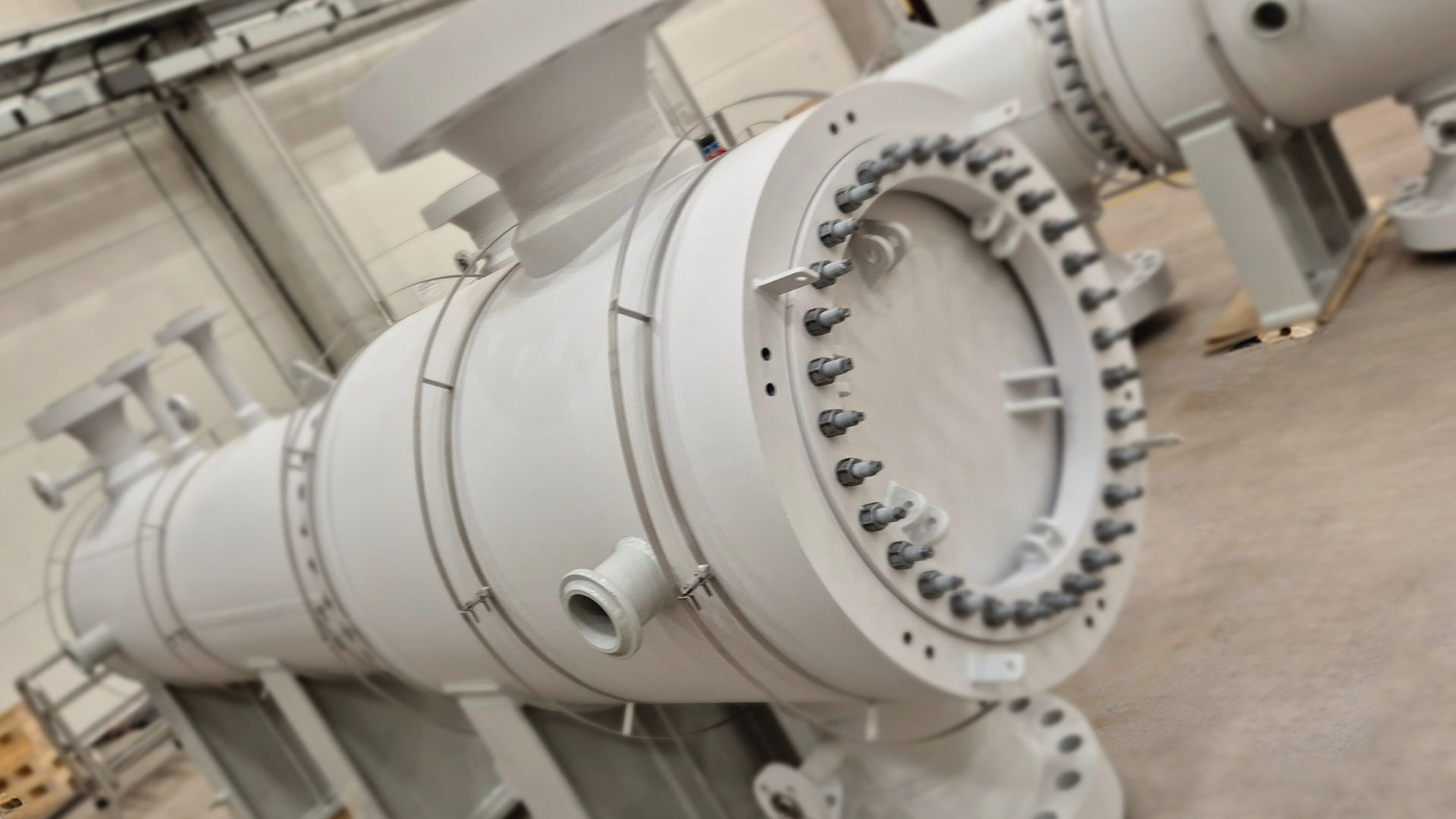

HEXONIC provides heat transfer solutions that support stable and safe operation of high-pressure process systems—from interstage/after-compression cooling to heat recovery where it is technically and economically justified.

Why CO₂ Temperature Control Matters in CCS/CCUS

During compression, CO₂ temperature increases significantly, and subsequent stages require controlled cooling and stabilization. Poor temperature management can lead to:

-

reduced process efficiency and higher energy consumption,

-

unstable operation,

-

increased risk of unfavorable phenomena during expansion conditions (e.g., formation of dry ice—solid CO₂).

That’s why CCS/CCUS facilities use heat exchangers to manage temperature at key points in the process.

Heat Exchanger Applications in CO₂ Systems

CO₂ Compression Cooling (aftercoolers / intercoolers)

-

stabilizes temperature between compression stages,

-

improves reliability and operational safety,

-

prepares CO₂ for downstream steps.

CO₂ Conditioning for Transport and Injection

-

supports controlled temperature profiles and limits parameter fluctuations,

-

enables robust operation under high-pressure conditions.

Heat Recovery from the Process

-

captures usable heat (where it makes business sense),

-

improves overall energy balance of the installation.

European CCS Example: Porthos (Port of Rotterdam)

One of Europe’s best-known CCS projects is Porthos in the Rotterdam area. The project is developed by Port of Rotterdam, Gasunie and EBN, and its CO₂ supply chain lists companies such as Shell, ExxonMobil, Air Liquide and Air Products as CO₂ suppliers to the system.

Porthos illustrates the direction of the market: growing demand for reliable process infrastructure, including solutions that support CO₂ compression and stable operating parameters.

How Hexonic Supports CCS/CCUS Projects

CO₂-related applications require integrity, durability and fit-for-duty design for high-pressure operation. In CCS/CCUS projects, what matters most is:

-

selecting a heat exchanger for operating pressure, medium and temperature regime,

-

robust performance under demanding process conditions,

-

an engineering approach aligned with quality and process safety requirements.

If you are planning a CCS/CCUS investment or upgrading a compression section, we can support the selection of a heat transfer solution matched to your operating parameters.

FAQ

What heat exchangers are used in CO₂ compression?

Most commonly, heat exchangers are selected for interstage and after-compression cooling (intercoolers/aftercoolers) to stabilize CO₂ temperature and operating conditions.

Why cool CO₂ after compression?

Cooling improves process stability, reduces operational risk, and supports CO₂ conditioning for transport and injection.

Can heat exchangers improve the energy efficiency of CCS?

Yes—through better compression-stage temperature management and through heat recovery where it is technically and economically justified.

Contact

Contact Hexonic if you are looking for solutions for:

-

CO₂ after-compression cooling,

-

high-pressure process systems,

-

CCS/CCUS and industrial decarbonization projects.