Refining industry

Crude oil refining is an expensive and power-consuming process.

Crude oil refining is an expensive and power-consuming process.

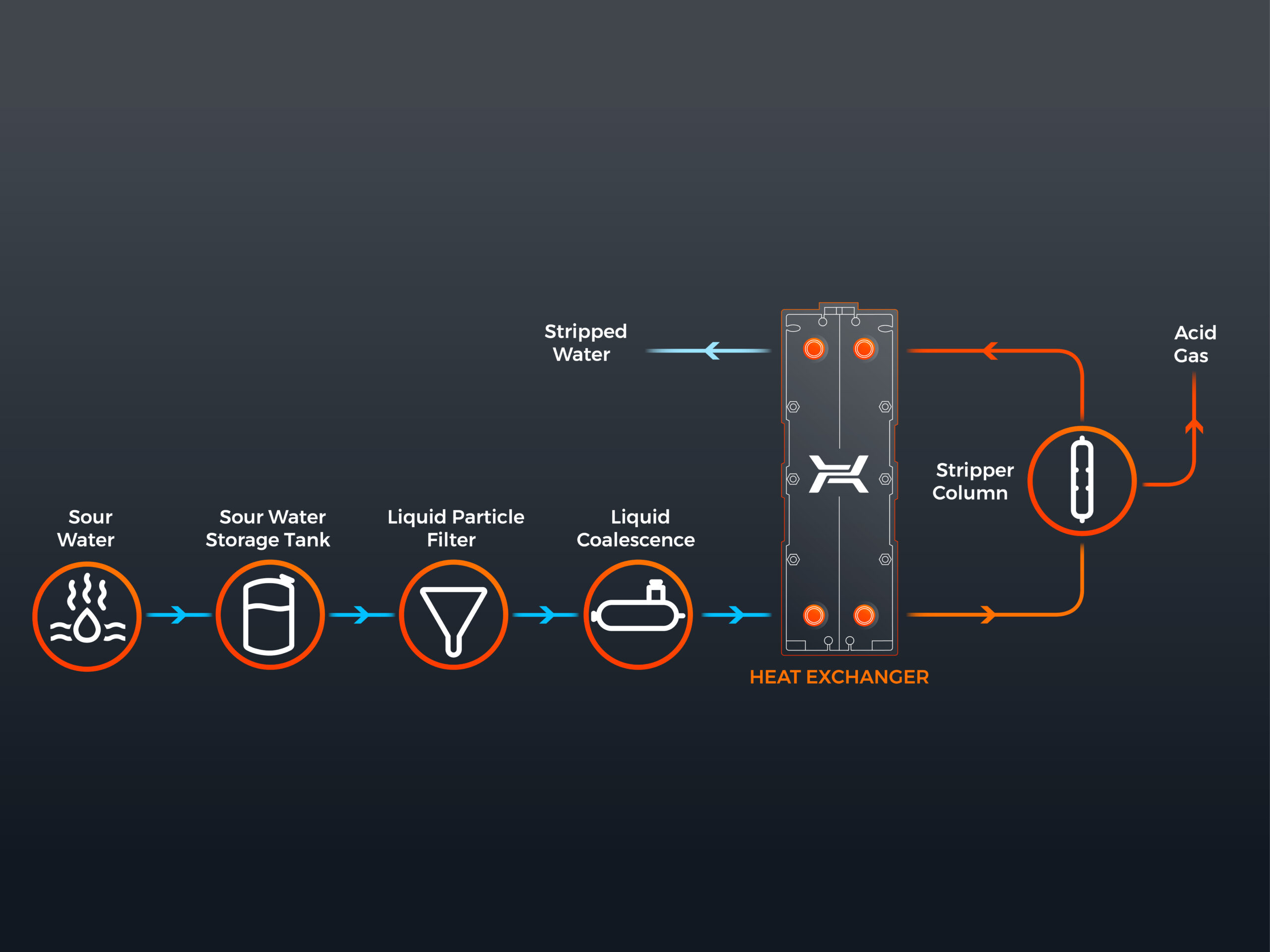

Refineries are constantly improving their operational efficiency, while observing strict standards related to reducing emissions of harmful substances and sulfur content in fuels. Due to the necessity to observe sulfur management rules and ensure maximum water re-use, the sour water stripping process is used. It consists in removing ammonia and hydrogen sulfide from the process water. The sour water from process units is collected in a tank. From there, it is pumped through a heat exchanger to the upper part of the stripper column. Energy recovery takes place when sour water is heated before stripping. Sour exhaust gases from the stripping unit may be routed to the sulfur recovery unit (SRU), afterburning furnace or sour gas flare. Sulfur recovery units are the most environmentally-friendly method of gas disposal. In the remaining cases, SO2 and NOx emissions may significantly increase.

Hexonic has the necessary knowledge that ensures optimal heat exchange in the refining industry. Our technology allows for maximizing energy efficiency and minimizing corrosion and pollution issues. Our shell and tube exchangers, designed for many technological applications, have repeatedly proven to be reliable under the most harsh process conditions.