DC – Dual Circuit heat exchangers

Dual Circuit heat exchangers are advanced brazed plate heat exchangers that combine two independent refrigerant circuits with a common secondary-side circuit.

Their design ensures full counter-flow and maintains high efficiency under both full and partial load conditions. This solution combines a compact construction with operating flexibility and increased system reliability.

Features

- High efficiency under full and partial load

- Dual circuit operation

- Designed to reduce the risk of freezing damage

- Compact “two-in-one” design – fewer pipes and simpler installation

- Lower installation and service costs

- Optimal heat transfer thanks to symmetrical flow

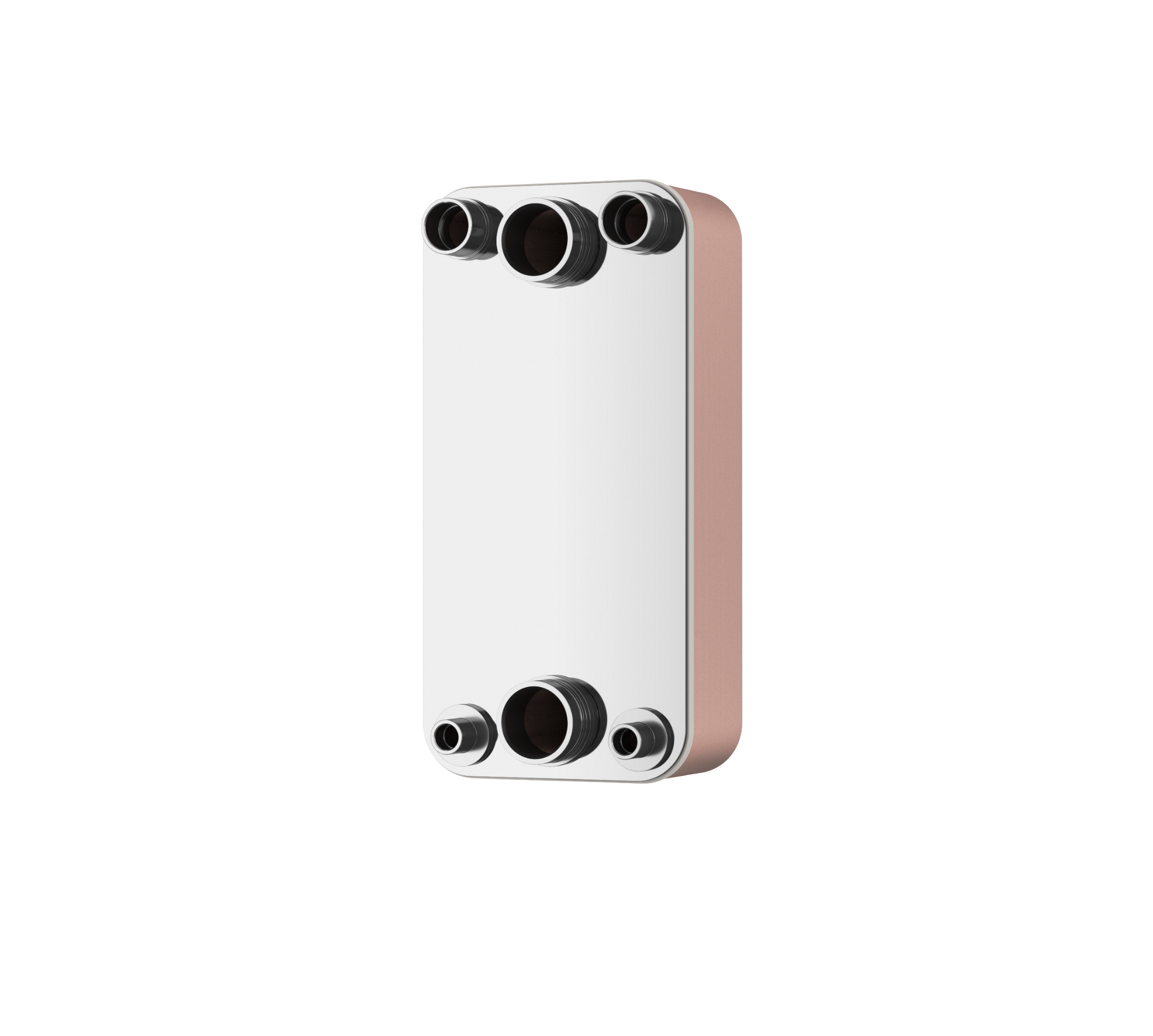

Design

-

Heating plates

-

Cover plates

-

Refrigeration connections

-

Water connections

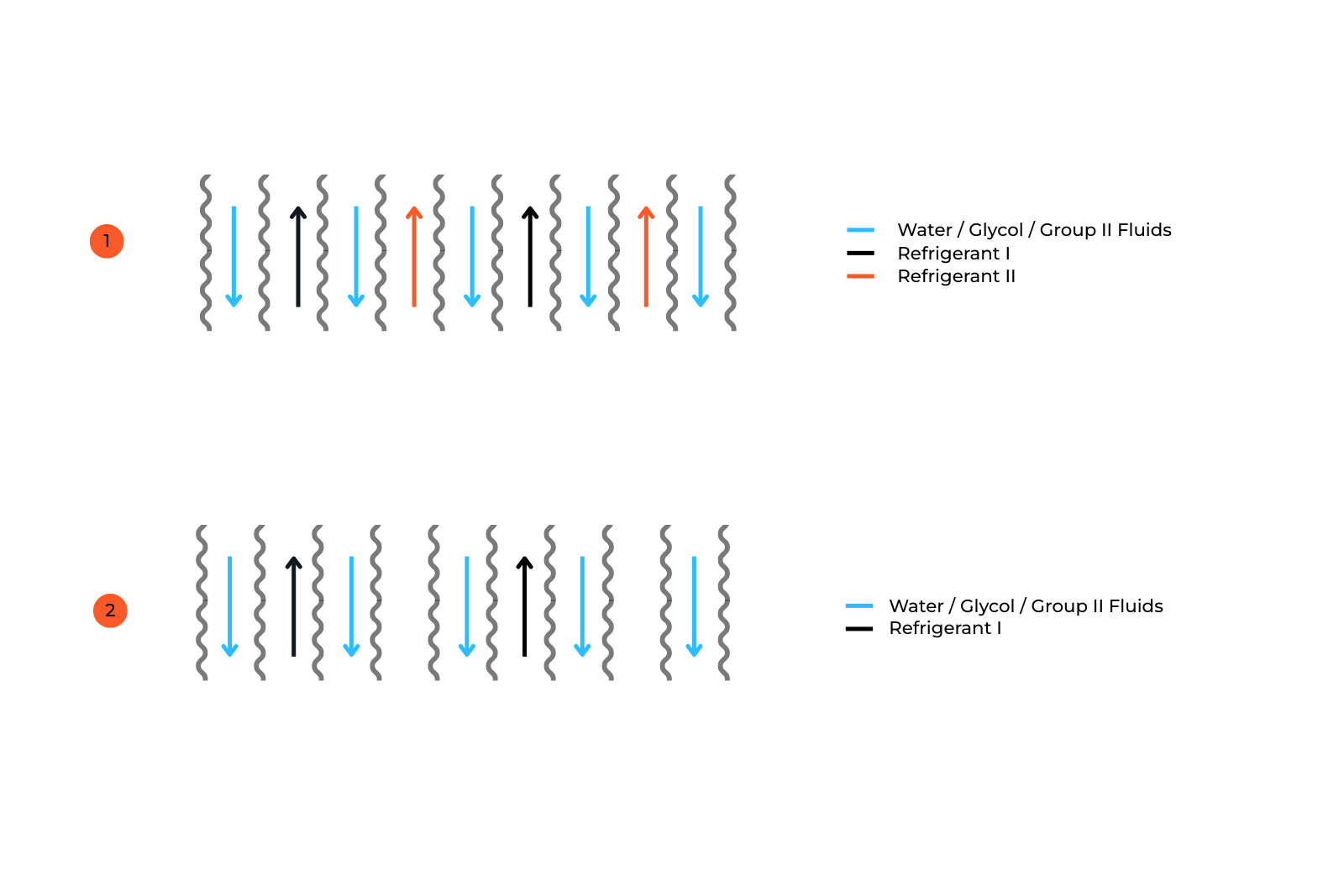

Flow of media in the DC exchanger

1. Flow diagram of the media inside the DC heat exchanger during simultaneous operation of both refrigerant circuits.

2. Flow diagram of the media inside the DC heat exchanger during operation of only one refrigerant

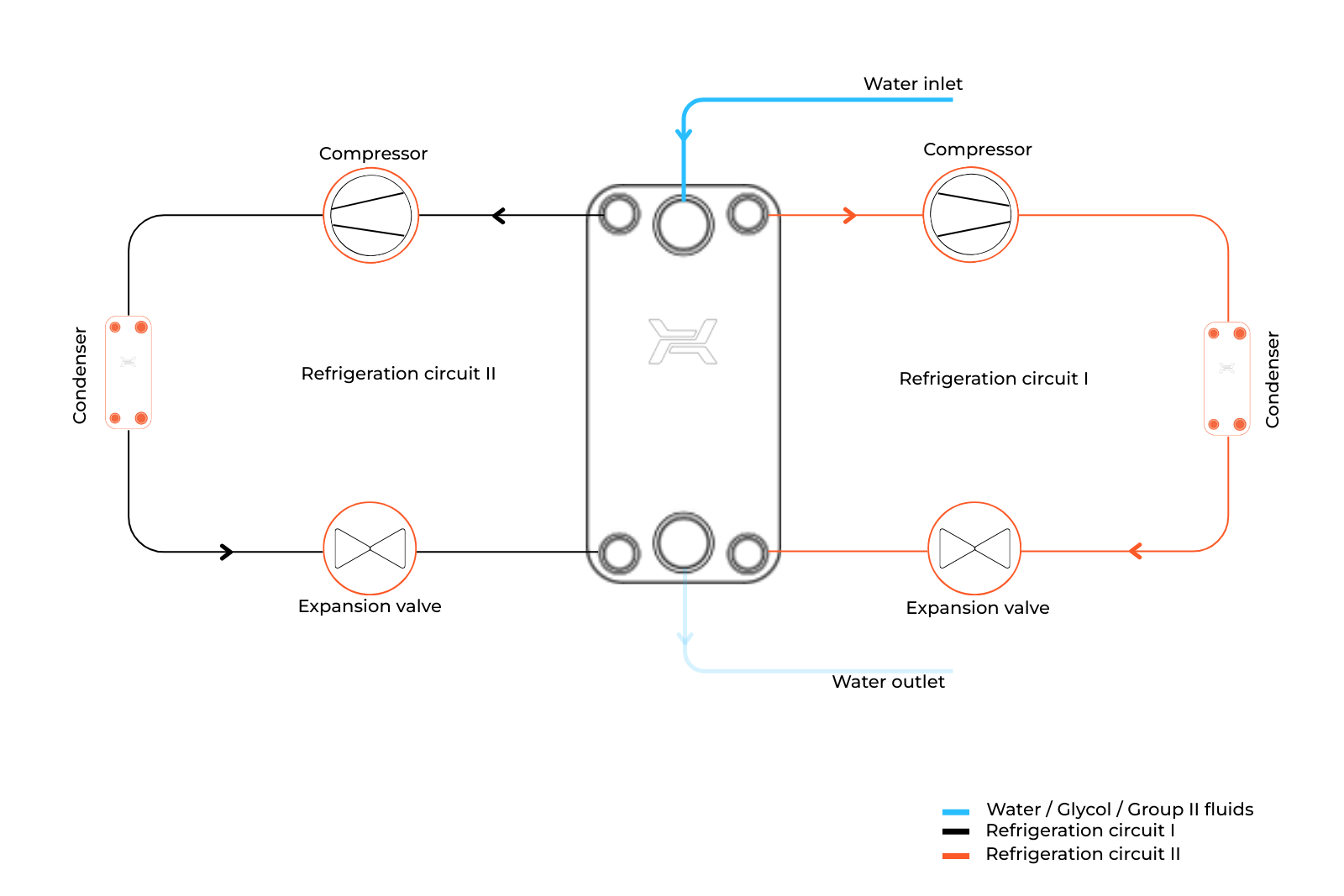

DC system diagram – operation of both circuits

In larger refrigeration systems, two independent refrigerant circuits are often used to better respond to variable loads and increase system reliability. In the event of a failure in one circuit, the other can still maintain performance.

Traditional solutions, such as two parallel heat exchangers, take up more space and increase the risk of freezing during partial operation. Dual Circuit heat exchangers integrate both circuits within a single unit while maintaining full counterflow and even contact with the secondary fluid.