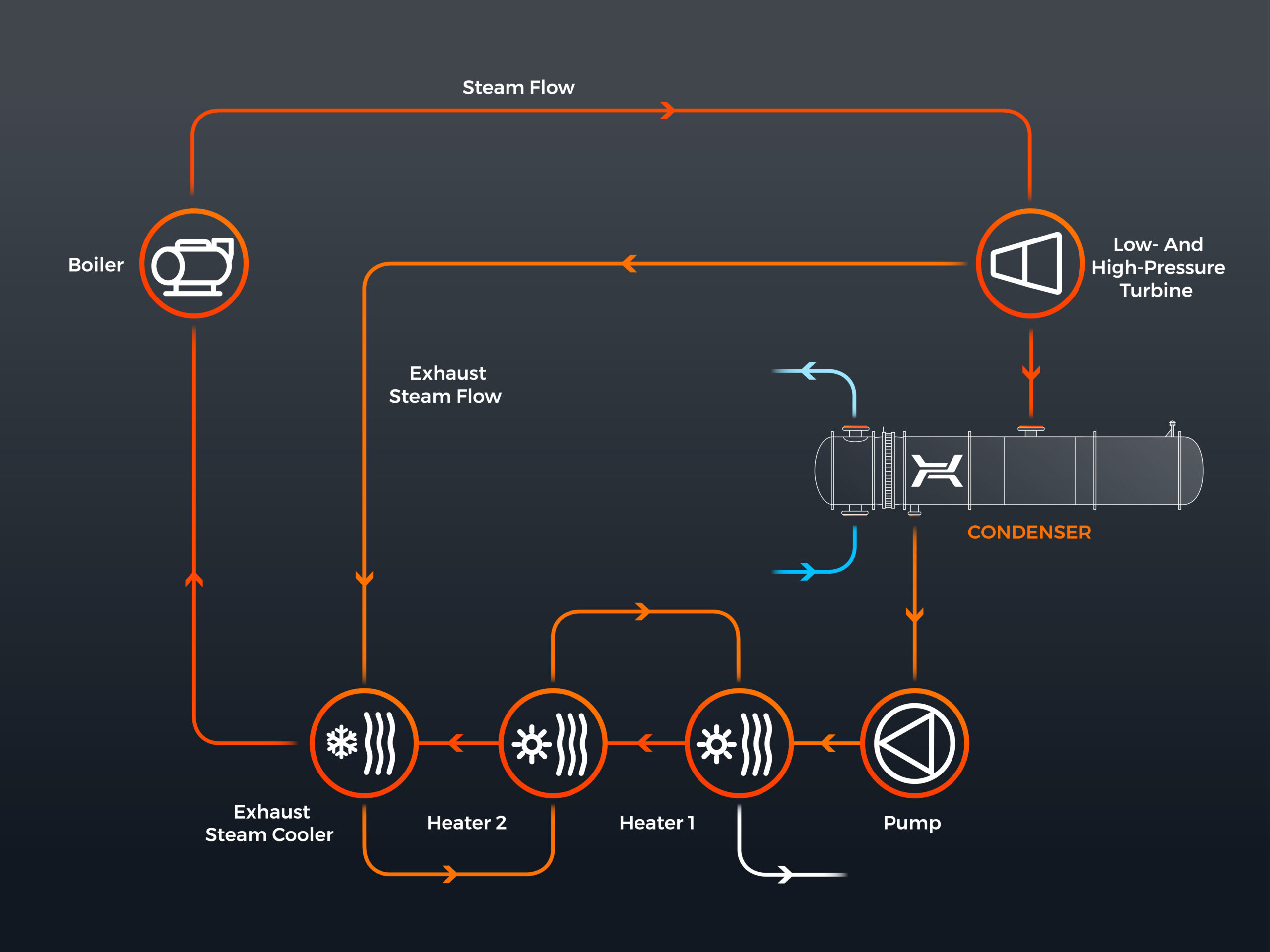

In a conventional power plant an increase in efficiency is mostly obtained by improving the parameters of the steam generated in the boiler and the steam used for propelling the turbine-generator.

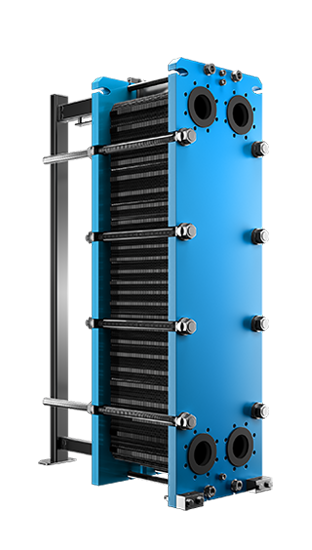

Increase in efficiency of the system also is also attained using multi-pass heating between stages and modification of the flow parts of steam turbines. Heat regeneration in regenerative heat exchangers is supposed to carnotize the thermodynamic cycle. It allows for a significant increase in the thermal efficiency of the actual steam power plant cycle. In practice this involves including a heat exchanger supplied with steam from the turbine outlet into the system. The heat collected from steam liquefication is transmitted to the condensate. Higher condensate temperatures reduce the amount of fuel necessary to heat the water. Based on condensate pressure, we may differentiate low-pressure regenerative heat exchangers and high-pressure regenerative heat exchangers.

Feed water is first heated with exhaust steam condensate in the 1st heater, and later on in the 2nd heater by condensation of the steam. Downstream of the 2nd heater there is the 3rd exhaust steam cooler, where the feed water is heated to a temperature slightly higher than the saturation temperature corresponding to the exhaust steam pressure.