Hexonic's condensing economizers are modern solutions supporting the energy transition in industry and district heating.

They are a key element in boiler plant modernization – increasing energy efficiency and reducing operating costs. Thanks to advanced design, they recover both sensible and latent heat contained in flue gases, which are typically lost in traditional systems. The E-LINE series transforms standard boilers into efficient condensing units by redirecting the recovered heat to the feedwater or air preheaters. As a result, system efficiency is approximately 9% higher compared to traditional solutions.

Higher efficiency means lower fuel consumption, reduced emissions, and tangible savings – especially in large industrial installations. In typical applications, condensing economizers can improve heat and steam recovery efficiency by up to 20%, making them a cost-effective investment with a short payback period.

Features

- Significant energy savings and reduced operating costs

- Return on investment in less than 3 years

- Enables modernization of existing boilers to condensing standard

- Corrosion resistance due to the use of stainless steel (316L)

- Unique teardrop-shaped horizontal tube design ensures high heat exchange efficiency

- Low flow resistance and minimal pressure drops

- Compact design – small footprint and easy installation

- Flexible installation – connection options adapted to site requirements

- High durability and reliability under demanding operating conditions

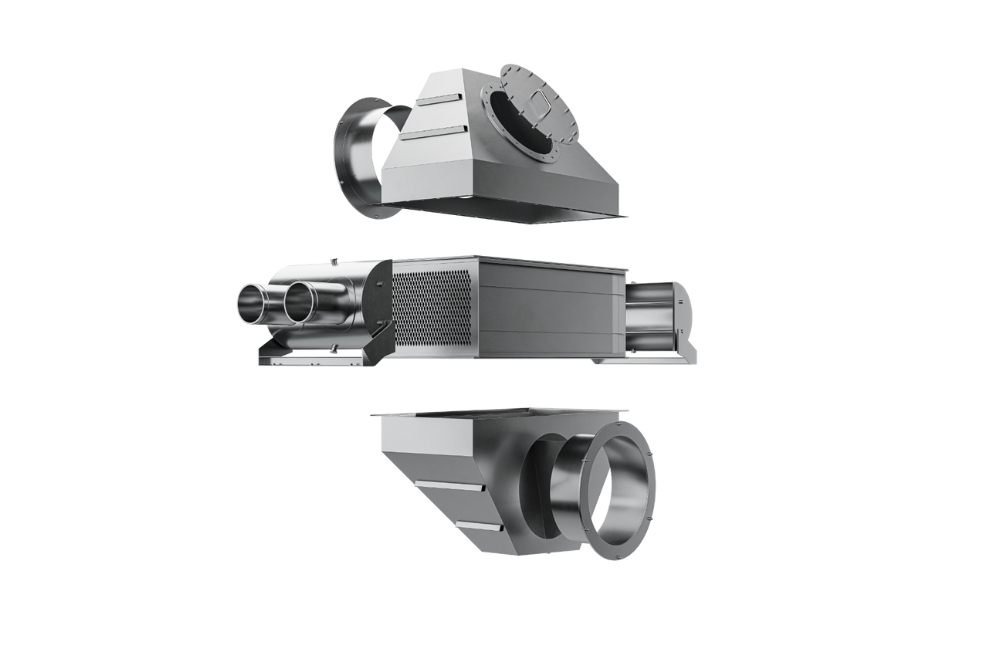

Construction

-

FLUE GAS INLETA gas duct for distributing flue gases

-

WATER INLETWater system for water distribution

-

WATER OUTLETWater system for water distribution

-

FLUE GAS OUTLETA gas duct for distributing flue gases

-

HEAT EXCHANGER WITH A UNIQUE “TEARDROP” TUBE PATTERNSpecially shaped tube arrangement maximizes the contact surface for heat exchange with the gases, enhancing energy recovery efficiency.

HEAT EXCHANGER WITH A UNIQUE “TEARDROP” TUBE PATTERNSpecially shaped tube arrangement maximizes the contact surface for heat exchange with the gases, enhancing energy recovery efficiency.

Frame

The frame is made of galvanized steel, providing corrosion resistance and solid, stable support for the heat exchanger. This structure facilitates installation and transportation and protects the device from mechanical damage and harsh environmental conditions.

Housing

The housing is made of galvanized steel with a powder-coated finish, combining effective anti-corrosion protection with a modern appearance. The housing is additionally insulated to prevent excessive heating of its walls, while the modular design allows for easy assembly, disassembly, and maintenance.

Operating Principle

Condensing economizers are heat exchangers that improve heating system efficiency by recovering energy from boiler flue gases. They operate by cooling the flue gases to a temperature at which the water vapor contained within condenses, releasing both sensible and latent heat. This allows for more efficient fuel utilization, reducing operating costs and emissions.

Flue gases flow on the outside of the exchanger tubes, while cold feedwater for the boiler flows inside. Heat is transferred through the tube walls, and the counterflow configuration of media ensures maximum energy recovery. Due to the acidic nature of the condensate, all components in contact with flue gases are made from corrosion-resistant stainless steel.