ST tube in tube heat exchangers find their application where fluids of high viscosity, density or high fiber or solid particle contamination are subjected to heat treatment, e.g. at wastewater treatment plants.

The presence of different types of mechanical contamination causes their sedimentation on the walls, which blocks the flows in the exchanger. Large diameter of the ST exchanger tubes ensures their free flow and the dismountable design allows for mechanical cleaning of the heat exchange surface.

Stainless steel make ensures corrosion resistance and the simple design ensures long-term failure-free operation.

Features

-

Dismountable designallows for mechanical cleaning

-

Option to increase heat exchange surfaceby adding further sections, the number of which depends on the media type and working parameters

-

Made of stainless steelensures corrosion resistance

-

Broad rangewith various nominal diameters and modules with 3 meters and 6 meters in length ensures flexibility in system design

Design

-

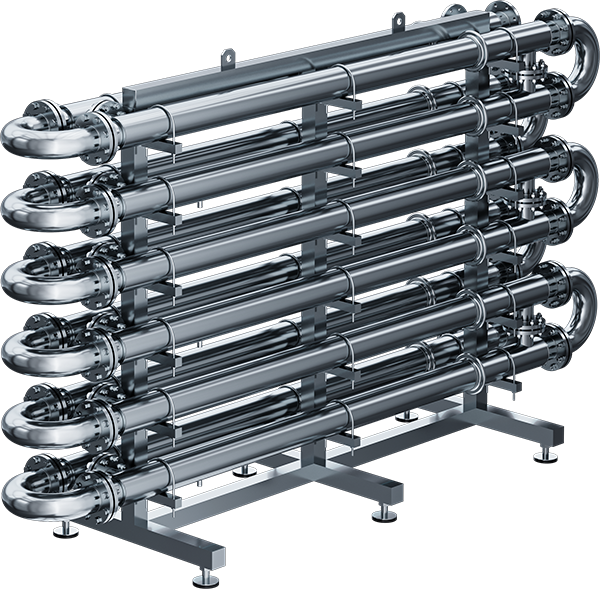

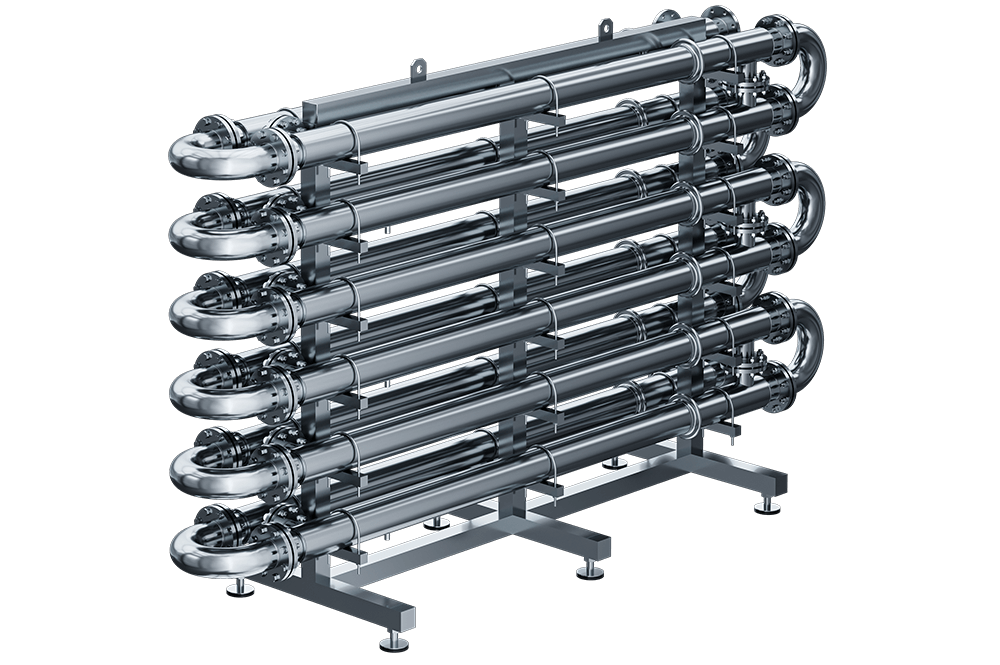

SectionThe exchanger consists of appropriate number of sections connected in series with knee tubes and set on a frame.

-

Frame

-

Knee tube

-

Expansion jointIt is used for the tubes when there is a significant temperature difference between the product side and the shell side.

-

Connection

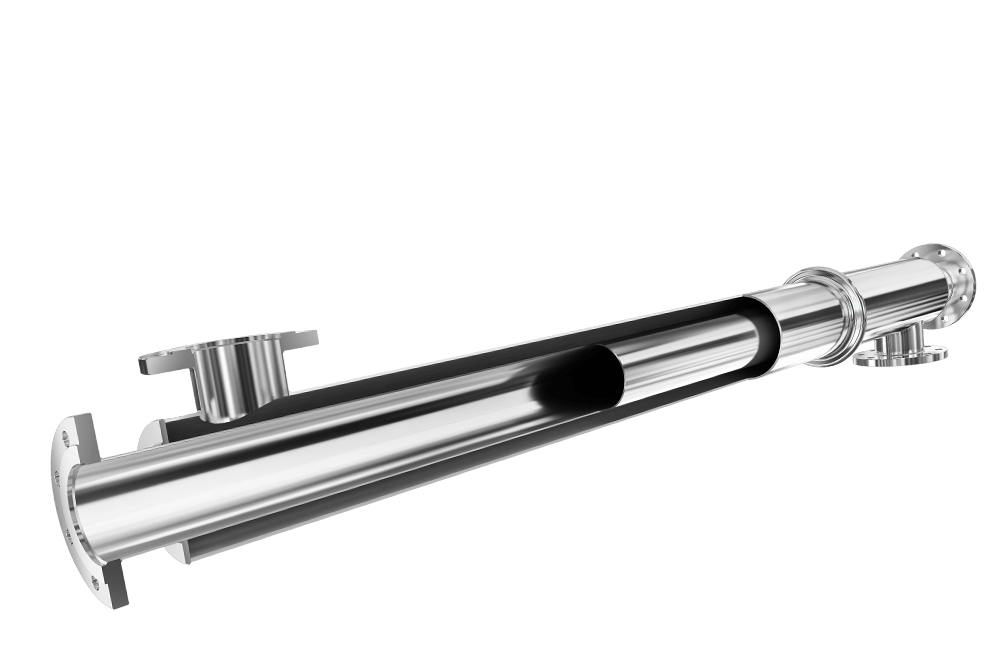

Tube in tube

The single section of the ST exchanger consists of two tubes with different nominal diameters. The tube with smaller diameter (product side) is installed inside the tube with the larger diameter (shell side).