Fermentation chambers

Places where organic substances contained in the sewage sludge undergo biological decomposition. The process takes place due to anaerobic methane fermentation.

Places where organic substances contained in the sewage sludge undergo biological decomposition. The process takes place due to anaerobic methane fermentation.

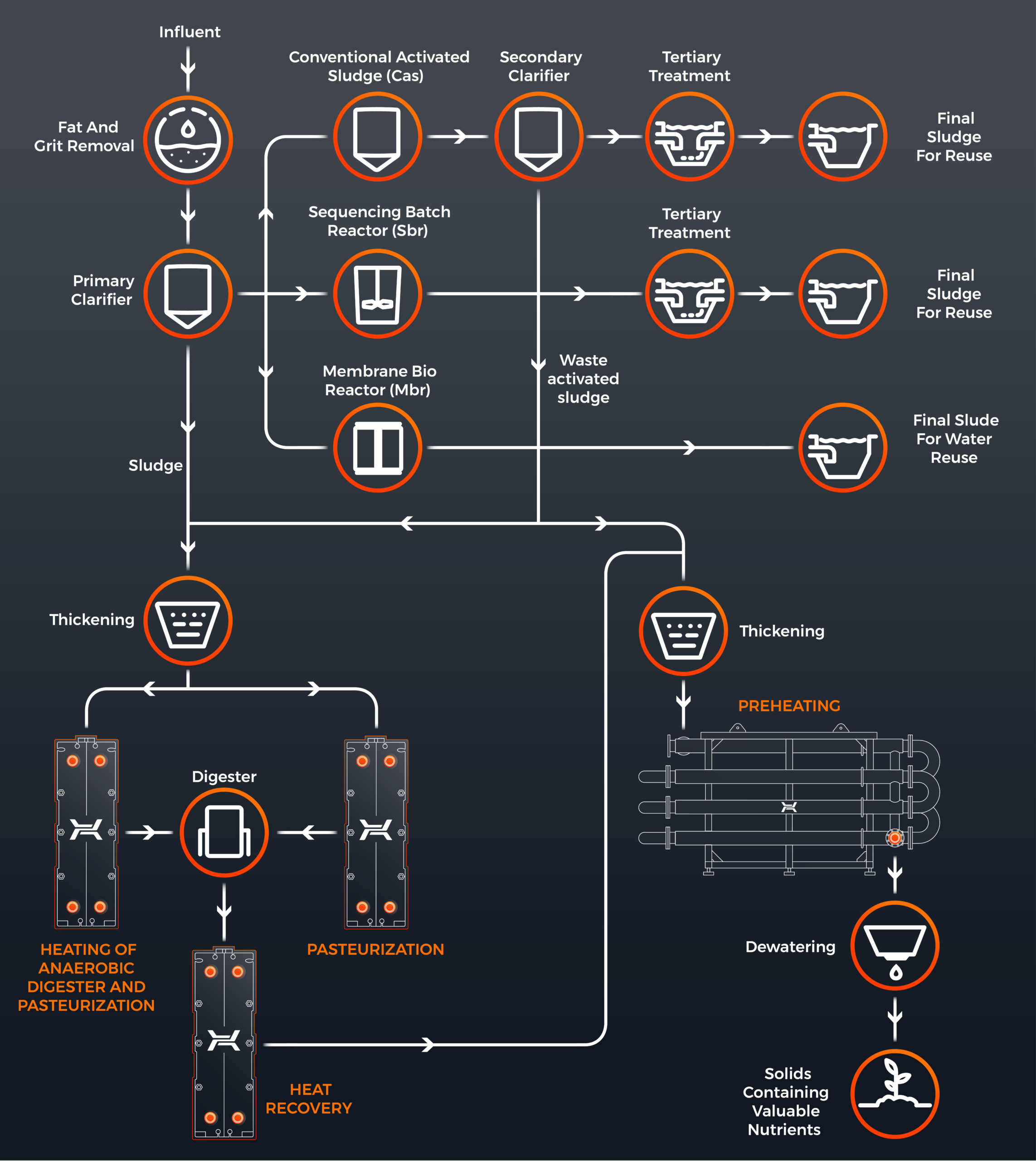

Anaerobic stabilization of municipal wastewater sludge allows to significantly reduce its harmfulness. During the sewage sludge treatment process, raw wastewater goes through the grit chamber, where the largest solids are removed. Later on the primary clarifier removes the sludge containing large amounts of organic substances. The sediments are directed straight to the fermentation chamber (a separate fermentation chamber). The remaining wastewater flows to the active sludge chamber or biological digestion tanks, where they undergo treatment using air oxygen and microorganisms. The remaining sludge has high water content, therefore before passing to the separate fermentation chamber, it is partially processes in filter presses. The resulting liquid is directed to the primary clarifier and the partially dewatered sludge goes to a separate fermentation chamber, where the average storage temperature is 37-38°C.

Methane fermentation occurring in the chamber without oxygen is a biochemical process of gasification of complex, multiparticle organic substances. The biogas generated in this process, consisting mostly of methane and carbon dioxide, goes up the fermentation chamber, and then is transported with pipes to the tank where it is stored. There is no heat exchanger installed in the chambers, unlike in agricultural biogas plants. The sediments are heated outside the chambers, in Hexonic ST heat exchangers.