Technology Meets Environmental Responsibility

On May 29, 2025, the ceremonial handover of the Czechnica-2 Combined Heat and Power Plant (gas-steam unit) in Siechnice marked a milestone in Poland’s energy transformation. This groundbreaking project, delivered by the Polimex-Mostostal S.A. and Polimex Energetyka consortium with technology partner Siemens Energy, represents a leap forward in clean energy infrastructure.

Project Overview

The new facility boasts impressive specifications:

- Electrical capacity: 179 MWe

- Thermal capacity: 315 MWt

- Coverage: Approximately 20% of heating demand for Wrocław metropolitan area and Siechnice municipality

- Investment value: ~1.4 billion PLN

- Future commitment: PGE Group plans to invest nearly 18 billion PLN in modern heating infrastructure by 2035

The Challenge: Low-Emission Energy Transformation

The project aimed to replace a century-old coal-fired power plant with clean gas-steam technology. Beyond the main gas-steam unit, the installation includes:

- 4 peak-reserve boilers

- 13,000 m³ thermal storage system for system flexibility and supply security

- Future-ready infrastructure prepared for green fuels like hydrogen

Environmental Impact

The transition to natural gas technology delivers remarkable environmental benefits:

- CO₂ emission reduction: 622,000 tons annually (-61%)

- Primary energy consumption reduction: ~600,000 MWh

- NOₓ emission reduction: 55%

- SO₂ emission reduction: 80%

- Particulate matter reduction: 20%

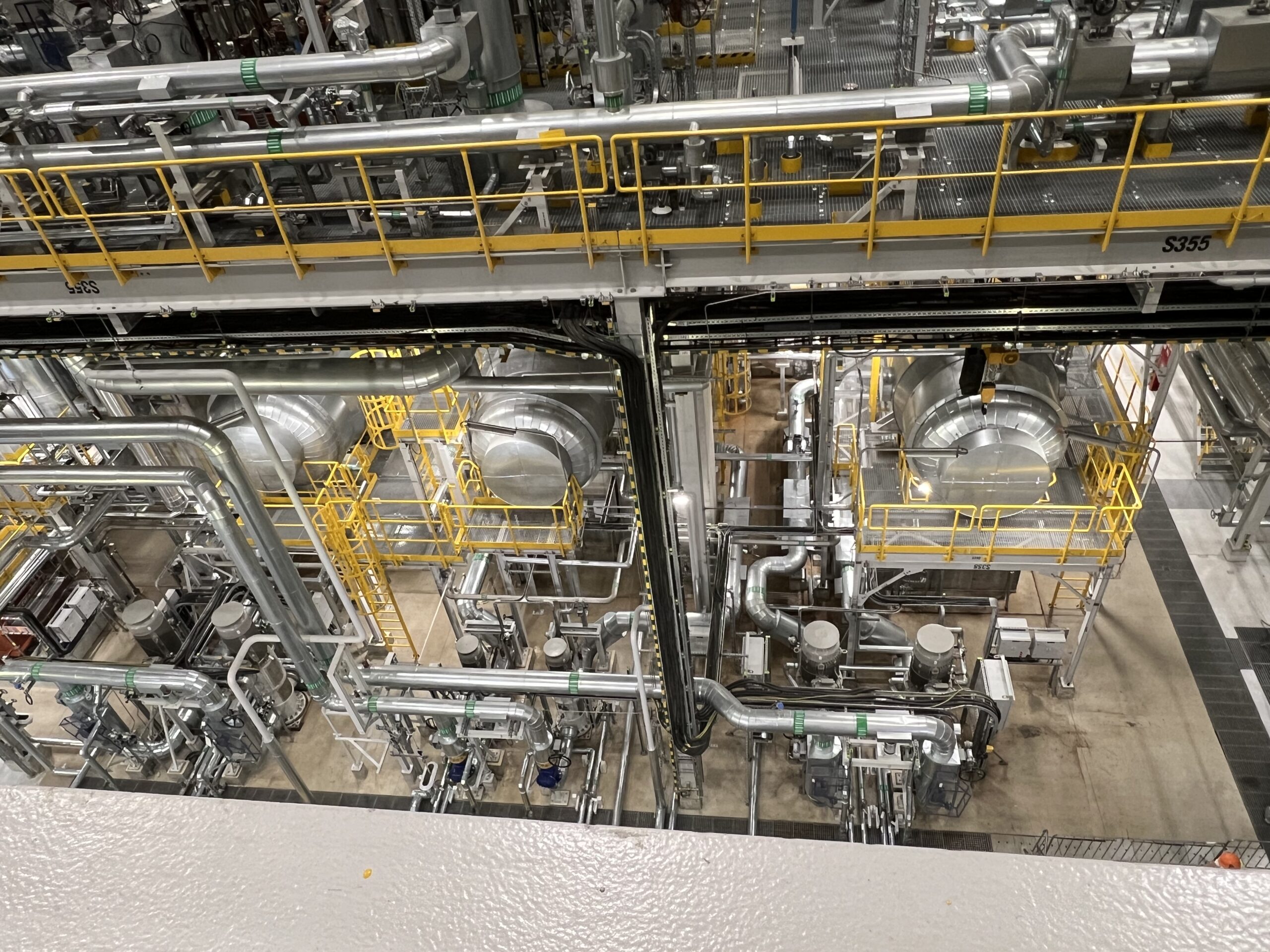

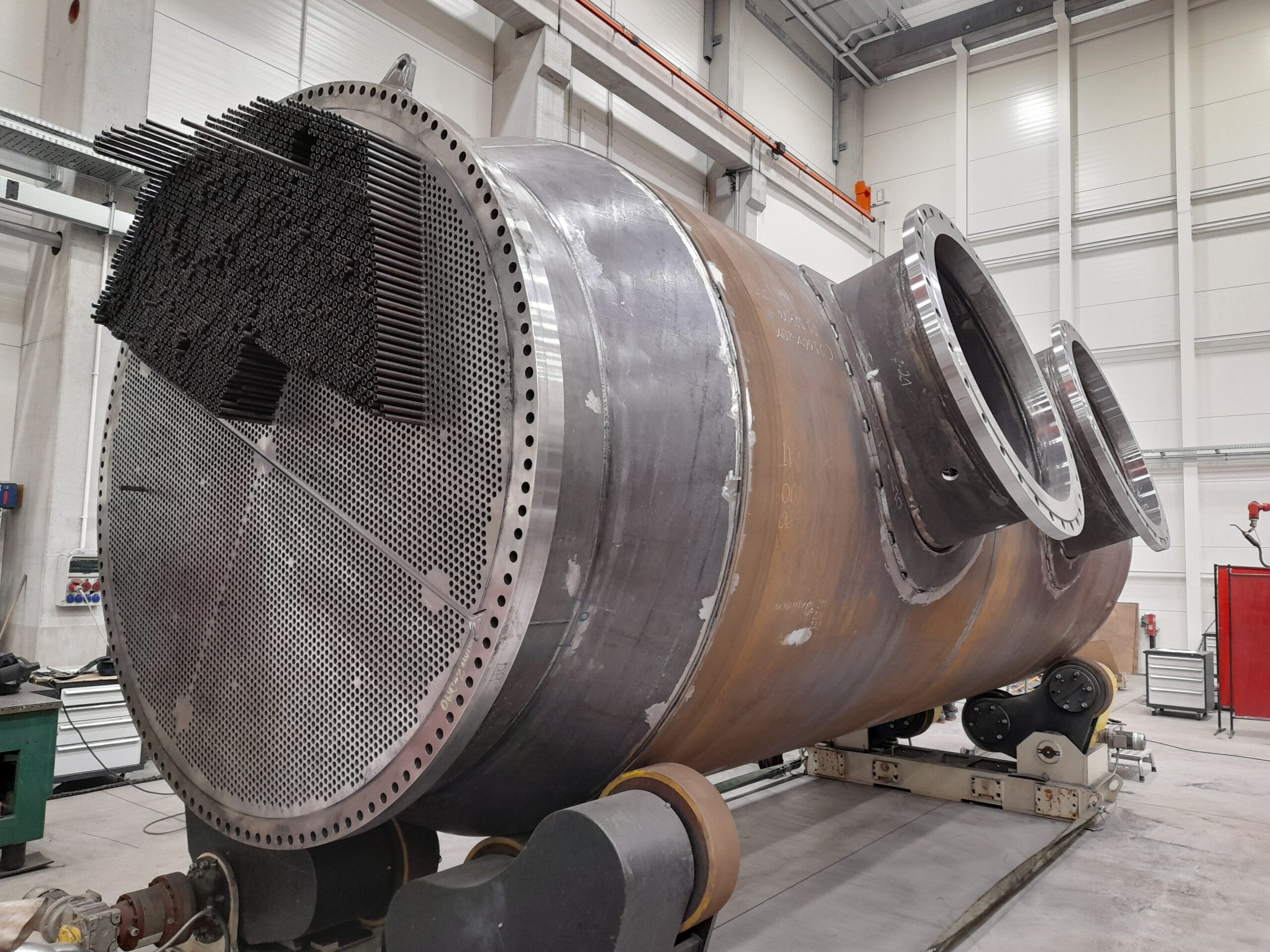

Hexonic’s Critical Contribution

As a key subcontractor, Hexonic delivered three massive district heating heat exchangers (DHC-1, DHC-2, DHC-3) – horizontal shell-and-tube condenser-type units specifically designed and manufactured for this strategic investment.

Technical Excellence

- Combined weight: 170 tonnes

- Total process tube length: 180 kilometers

- Combined thermal power: 315 MWt

Advanced Engineering Features

Construction Details:

- Shell-and-tube design with cylindrical welded carbon steel shells

- Straight stainless steel tubes ensuring corrosion resistance and high thermal conductivity

- Removable inlet, outlet, and return heads for easy maintenance and inspection

- Carbon steel tube sheets with stainless steel cladding on the medium side

Innovative Technology:

- Explosive cladding (platerowanie wybuchowe) permanently integrates the stainless steel layer with the base construction material

- This solution guarantees long-term resistance to corrosion and thermal stress

Project Results

Direct Impact:

- Heating supply for approximately 120,000 customers

- Significant reduction in CO₂, NOₓ, SO₂, and particulate emissions

- Infrastructure ready for future green technologies including hydrogen

- Revitalization of historic power plant infrastructure through collaboration between KOGENERACJA, PGE, and local authorities

Strategic Significance: This project demonstrates Poland’s commitment to energy transition while maintaining energy security and supporting local industrial capabilities.

Partnership Excellence

We extend our gratitude to Polimex-Mostostal for their trust and professional collaboration on this prestigious investment. The successful completion of Czechnica 2 Combined Heat and Power Plant proves the value of partnering with local manufacturers who combine experience, technological expertise, and readiness to deliver custom-tailored solutions.

Conclusion

The Czechnica 2 project exemplifies how advanced thermal management technology can drive environmental transformation while supporting regional development. Hexonic’s contribution to this landmark project reinforces our position as a trusted partner in Poland’s energy transition, delivering critical infrastructure that will serve communities for decades to come. This project represents another milestone in Hexonic’s portfolio of successful energy sector deliveries, supporting Poland’s path toward a sustainable energy future.