Heat exchange is a crucial process in pasteurization and many other industrial processes in the food industry.

We offer a range of stainless steel heat exchangers, which are crucial components in the food industry. Our equipment streamlines the processes of heating, cooling, and pasteurization.

Stainless steel heat exchangers are an extremely important element in the production process, providing not only effective and fast heating or cooling, but also durability and hygiene. Heat exchangers increase production efficiency while saving energy. The pasteurization process is crucial for ensuring food safety and extending its shelf life.

Advantages

● High efficiency

● Effective energy recovery

● High level of hygiene

● Made of stainless materials

● Corrosion resistance

● Certified gaskets

● Energy savings

● Expandability

● Wide range of products

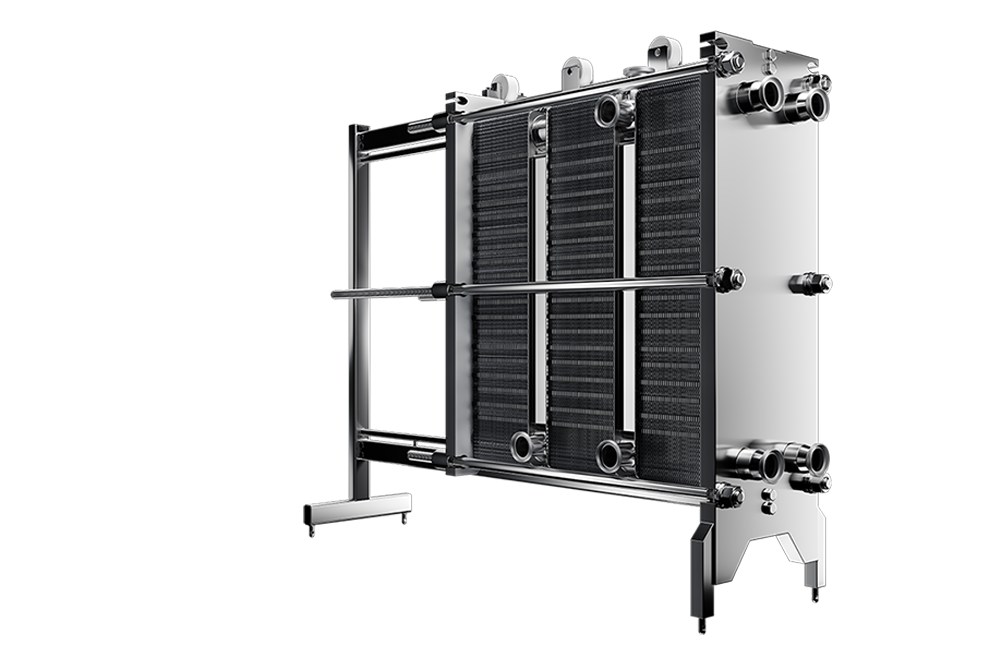

Design

-

Stainless steel cover plate

-

Heating plates

-

Connections

-

Structural frame

-

Roller bearing

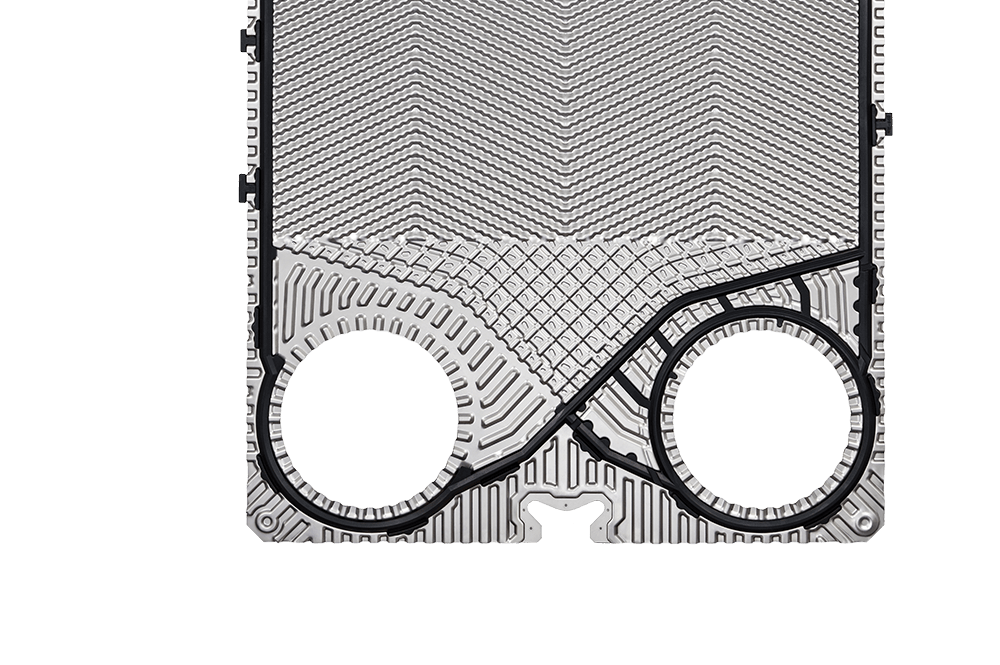

JAG plate - reinvented

-

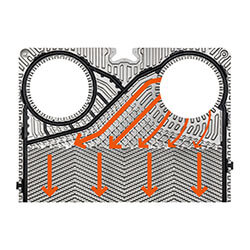

Innovative embossing pattern

Innovative embossing pattern

-

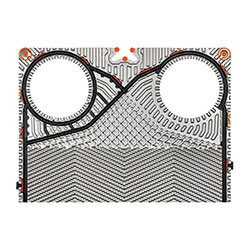

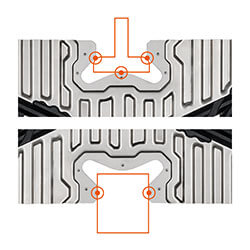

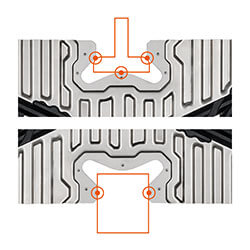

Triple system for positioning heating plates

Triple system for positioning heating plates

-

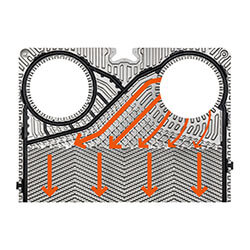

Modified distribution zone

Modified distribution zone

-

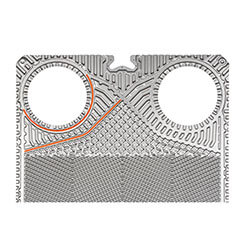

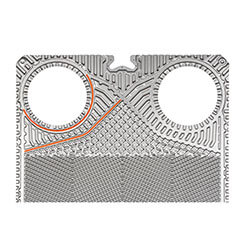

Optimized sealing surface

Optimized sealing surface

-

Additional strengthening of the plate

Additional strengthening of the plate

-

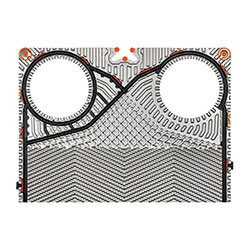

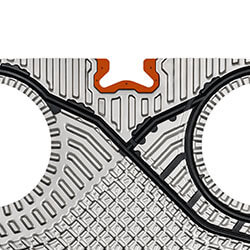

Patented hybrid gasket attachment systemnew patented seal features two attachment methods and an optimized, unique shape

Patented hybrid gasket attachment systemnew patented seal features two attachment methods and an optimized, unique shape

-

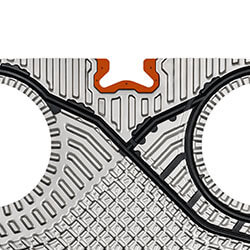

Five-point attachment system

Five-point attachment system

-

50-100 mm ports

-

Lock-in methodspecially designed pins are pressed into the appropriate cutouts in the hob, and lock-in locks stabilize the seal on the hob during installation

Lock-in methodspecially designed pins are pressed into the appropriate cutouts in the hob, and lock-in locks stabilize the seal on the hob during installation