CIP stations

CIP (Clean in place) stations are systems to wash systems and devices that constitute the equipment of industrial plants where hygienic standards play an important part.

CIP (Clean in place) stations are systems to wash systems and devices that constitute the equipment of industrial plants where hygienic standards play an important part.

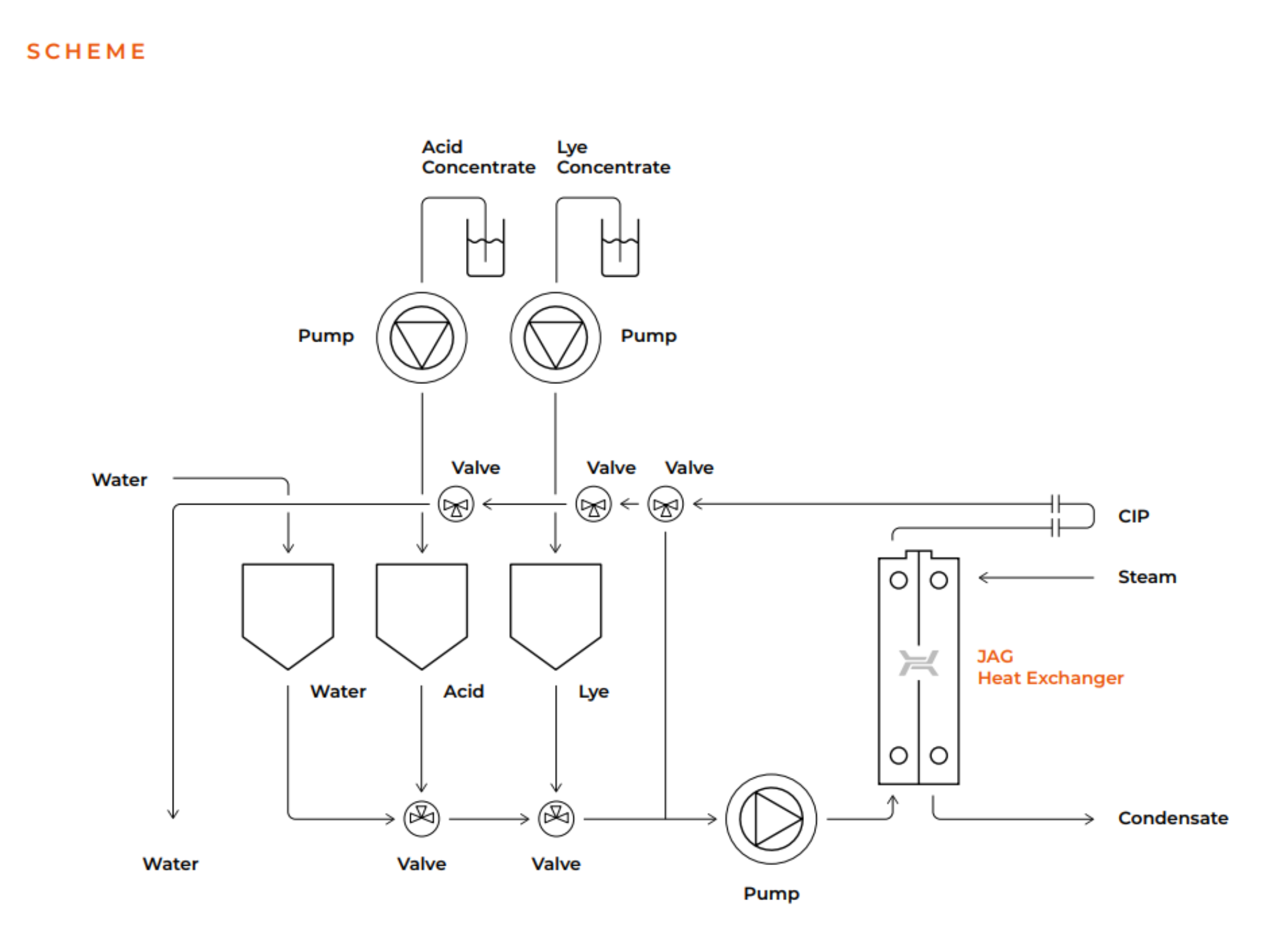

The automated process involves cleaning inner tube surfaces and other elements without the need to disassemble them. Cleaning in a closed cycle saves time, media, chemical agents and reduces waste water amount. These devices are used not only in food and brewing industry, beverage and dairy product manufacturing and processed food manufacturing, but also in pharmaceutical and cosmetic plants.

The cleaning cycle starts with initial flushing with water for interoperational flushing. The water from initial flushing goes directly into waste water. Dosing pumps deliver strictly defined amounts of chemical agents into the container. Then the cleaning solution heated by JAD shell and tube exchanger circulates in the closed cycle until the device is thoroughly cleaned at the assumed temperature. After the cycle is finished, the entire system is flushed until pH is at neutral level. During cleaning the CIP system is completely cut off from the production line.