Beverage manufacturing

Beverage manufacturers compete in employing the most modern technologies to increase system performance and optimize costs.

Beverage manufacturers compete in employing the most modern technologies to increase system performance and optimize costs.

Beverages are manufactured in precisely determined temperatures. Water for solution is cooled down in a heat exchanger. At the later production stages, syrup is added in separate containers. Water mixed with the syrup is then heated again and cooled down to the storage temperature, passing through a heat exchanger. In this case, the cooling medium absorbing heat from the beverage is glycol. Optimized heat exchange with low pressure loss ensures low operating costs, which is crucial in mass production.

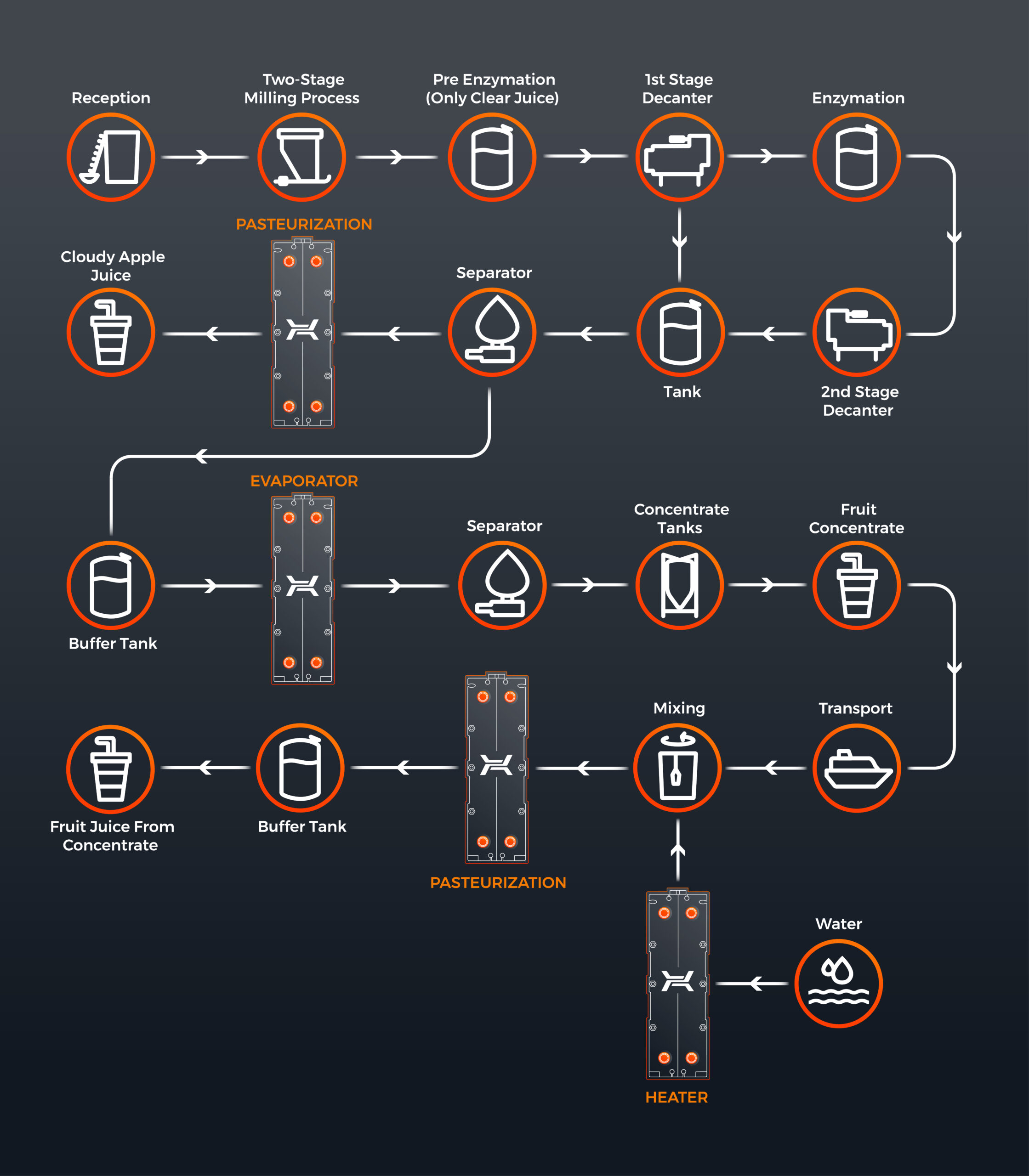

The vast range of Hexonic heat exchangers includes devices for pasteurization, cooling, heating juices, heating hot water, in CIP systems.