Hydraulic systems

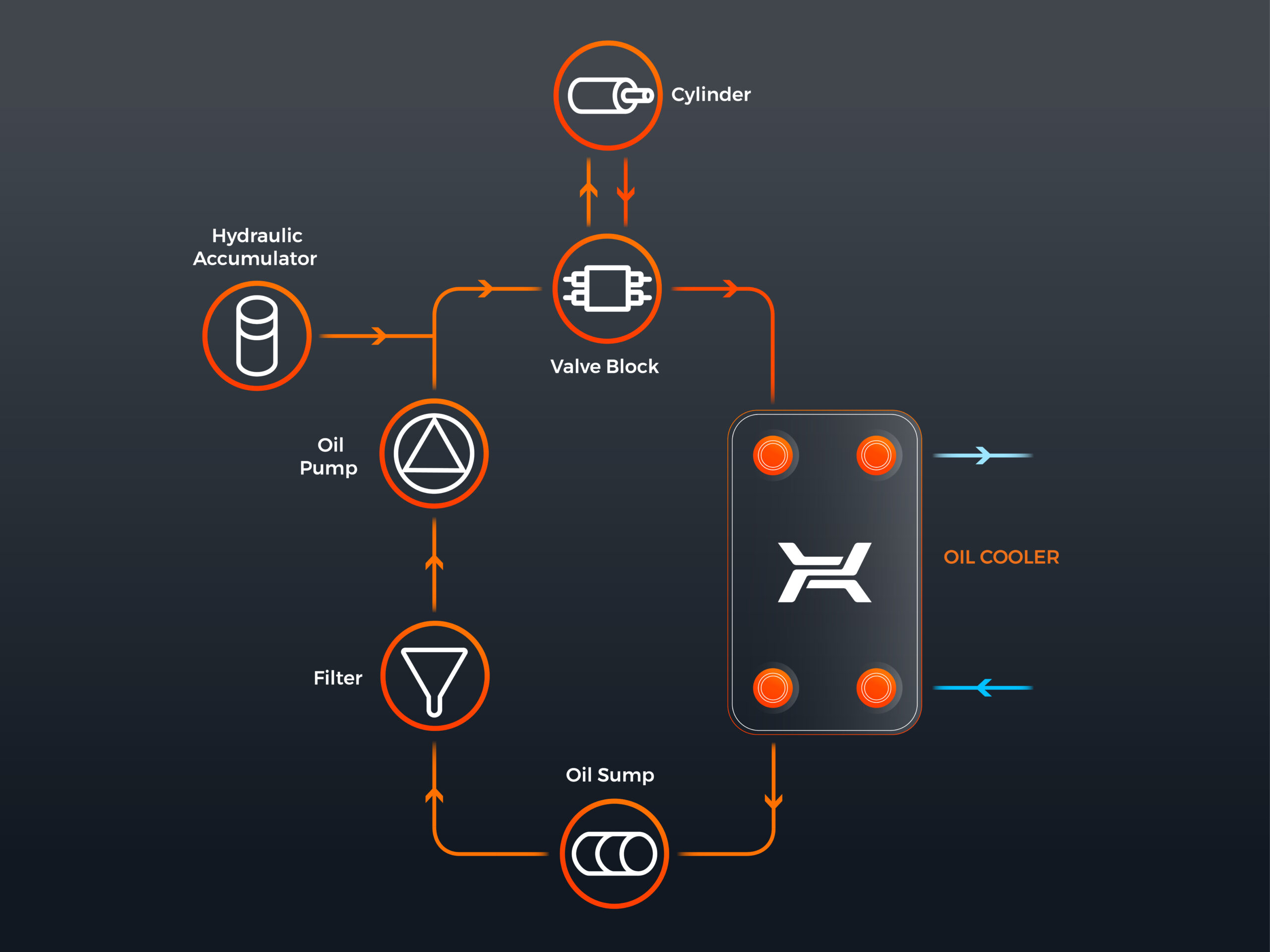

Hydraulic systems are relatively easy to install and maintain. Typically a hydraulic system consists of a pump, valves and cylinder filled with hydraulic oil.

Hydraulic systems are relatively easy to install and maintain. Typically a hydraulic system consists of a pump, valves and cylinder filled with hydraulic oil.

The biggest threat connected with improper operation of the system is high temperature. Oil temperature increase results from its constant flow through the system, friction between the system elements, prolonged operation etc. Increased temperature has a significant impact on change in oil viscosity, contributing to increased wear and tear of the device, degenerating the lubricating film, increasing the risk of cavitation and risk of internal leakage, thus shortening the life of the system.

Most of the problems connected with overheating of the hydraulic system may be solved by selecting an effective and efficient cooling system. A system equipped with an oil cooler may operate efficiently for a longer time, preventing overheating of the system. This is important for machines in the paper industry, hydraulic press, hydraulic aggregates etc.