Cogeneration units with gas engines

Cogeneration is one of the most effective energy utilization methods. Moving away from traditional electricity generation based on coal combustion is currently becoming an increasingly stronger trend.

Cogeneration is one of the most effective energy utilization methods. Moving away from traditional electricity generation based on coal combustion is currently becoming an increasingly stronger trend.

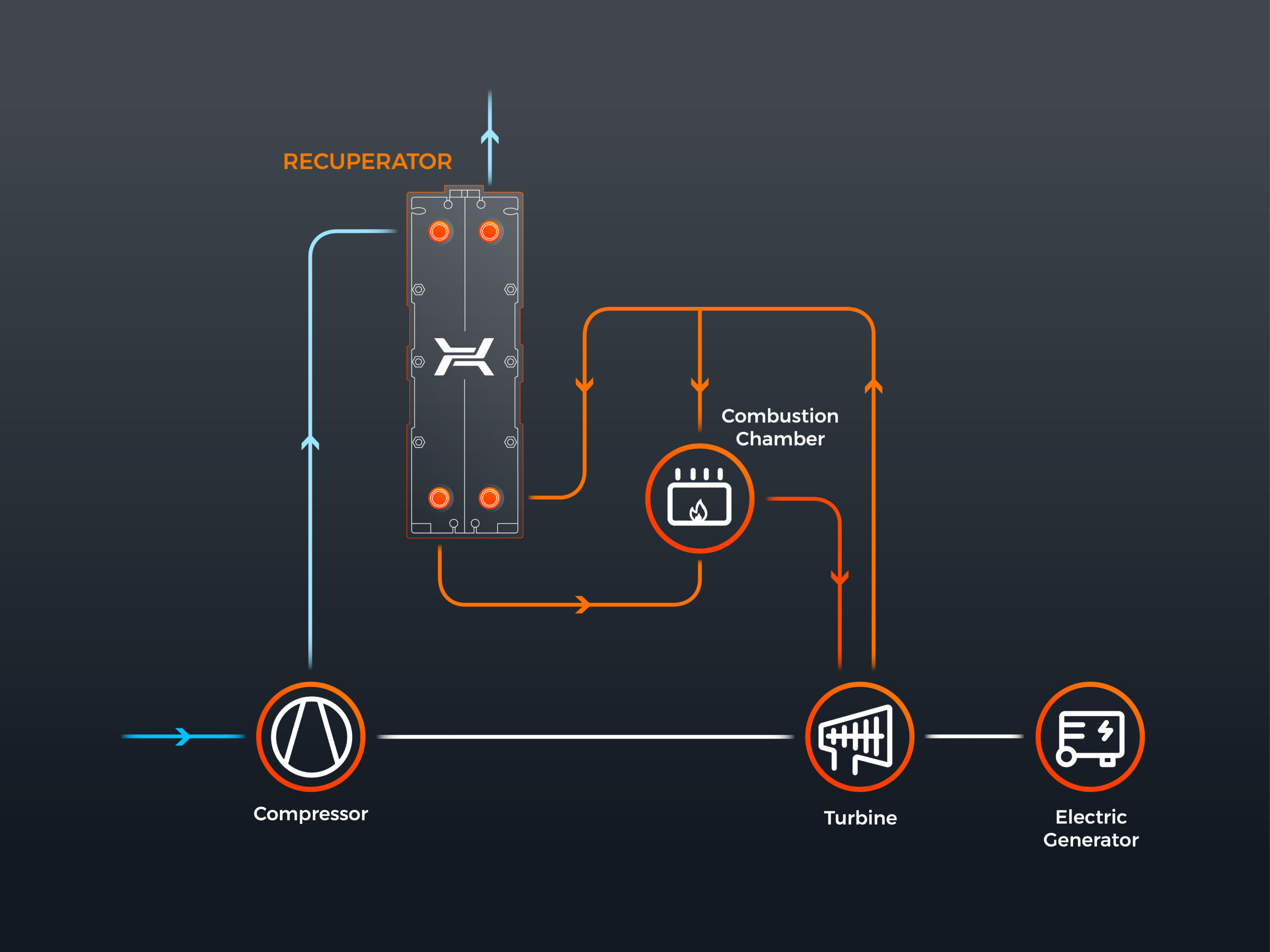

A basic gas-fired unit consists of a compressor, turbine and combustion chamber, usually mounted on one shaft. In order to optimize the power generation process, a range of improvements is introduced, with heat exchangers playing the main part. Flue gases, after decompression in the turbine, have a relatively high exergy. Heat recovery is a way to improve system efficiency. It is achieved by means of heating air before mixing it with fuel in the combustion chamber using flue gases from the turbine (Fig. 1). Due to the high operating parameters, such applications usually rely on shell and tube exchangers.

Another application of heat exchangers in gas-powered cogeneration units is the combustion chamber cooling system, i.e. engine block and lubricating oil cooling. Due to the relatively low parameters of the heat receiving medium, plate heat exchangers are used most often in such cases. The benefits of cogeneration units based on internal combustion engines include high electricity generation efficiency, compact design, low CO2 emission, high fuel diversity (natural gas, LNG, biogas, special gases), the possibility to generate energy at locations far away from transmission networks and to use them as a backup power supply.