Lubricating oil coolers

In power plants and combined heat and power plants equipped with a steam turbine or a gas turbine, lubricating oil coolers are the most important element, responsible for the performance of the whole industrial plant.

In power plants and combined heat and power plants equipped with a steam turbine or a gas turbine, lubricating oil coolers are the most important element, responsible for the performance of the whole industrial plant.

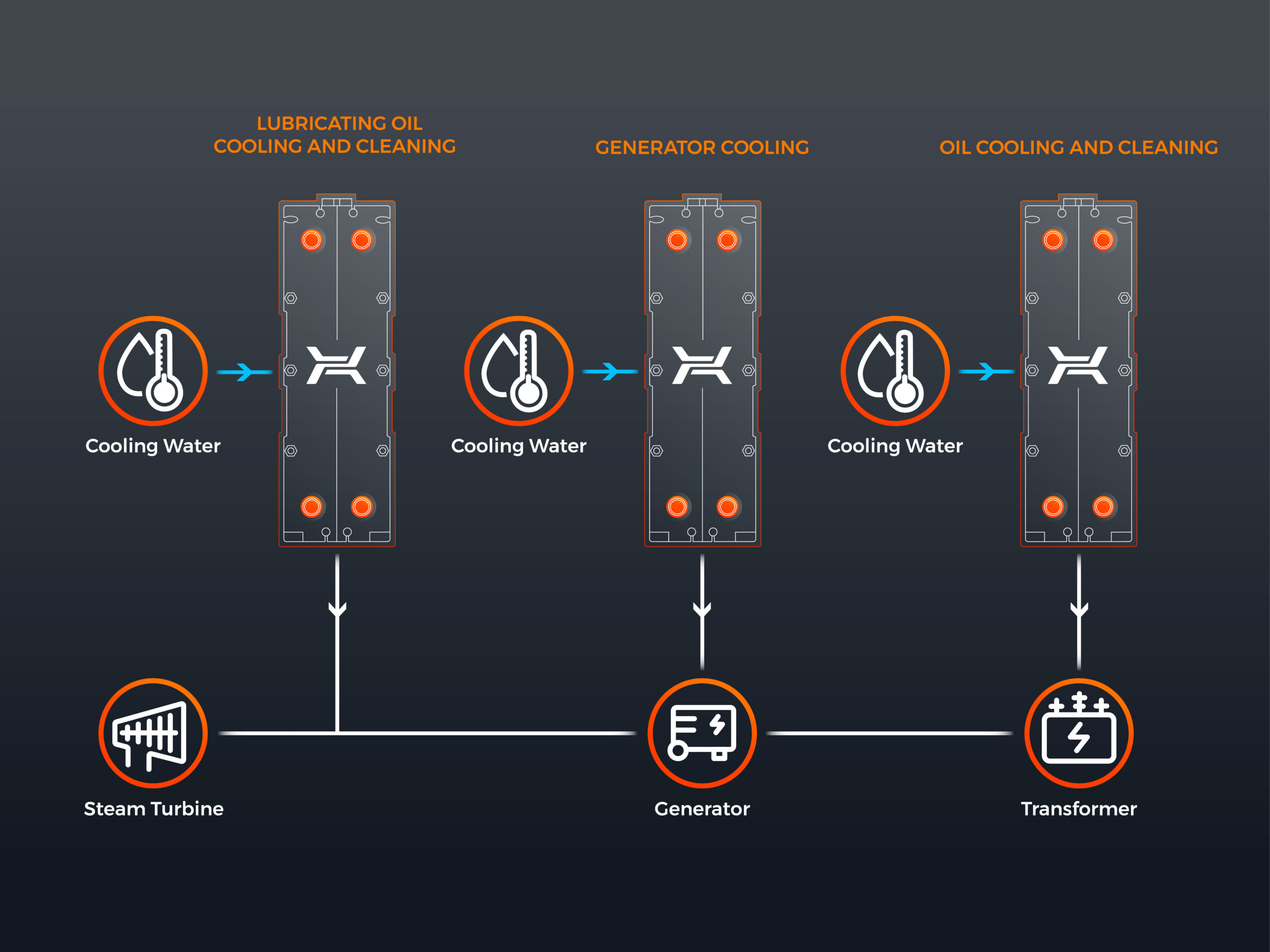

The lubricating oil is used for lubricating and cooling longitudinal and transversal bearings of the turbine, generator bearings and transmissions, gears and splined shafts. It is also used as hydraulic fluid in the hydraulic starter system of the turbine. The lubrication system consists of a large lubricating oil tank, coolers taking heat from the oil and circulating pumps. Under typical operating conditions, the oil is pumped to the lubrication system from the tank by the main oil pump.

Used oil returns to the tank through a gravitational discharge system in a closed cycle. It is cooled in the oil cooling circuit, controlled with a temperature control valve.

Reliable and safe operation of the system requires appropriate lubricating oil temperature at all times. Hexonic offers a broad range of heat exchangers in standard and custom versions, which have been operating in the most demanding lubricating oil cooling systems for many years.