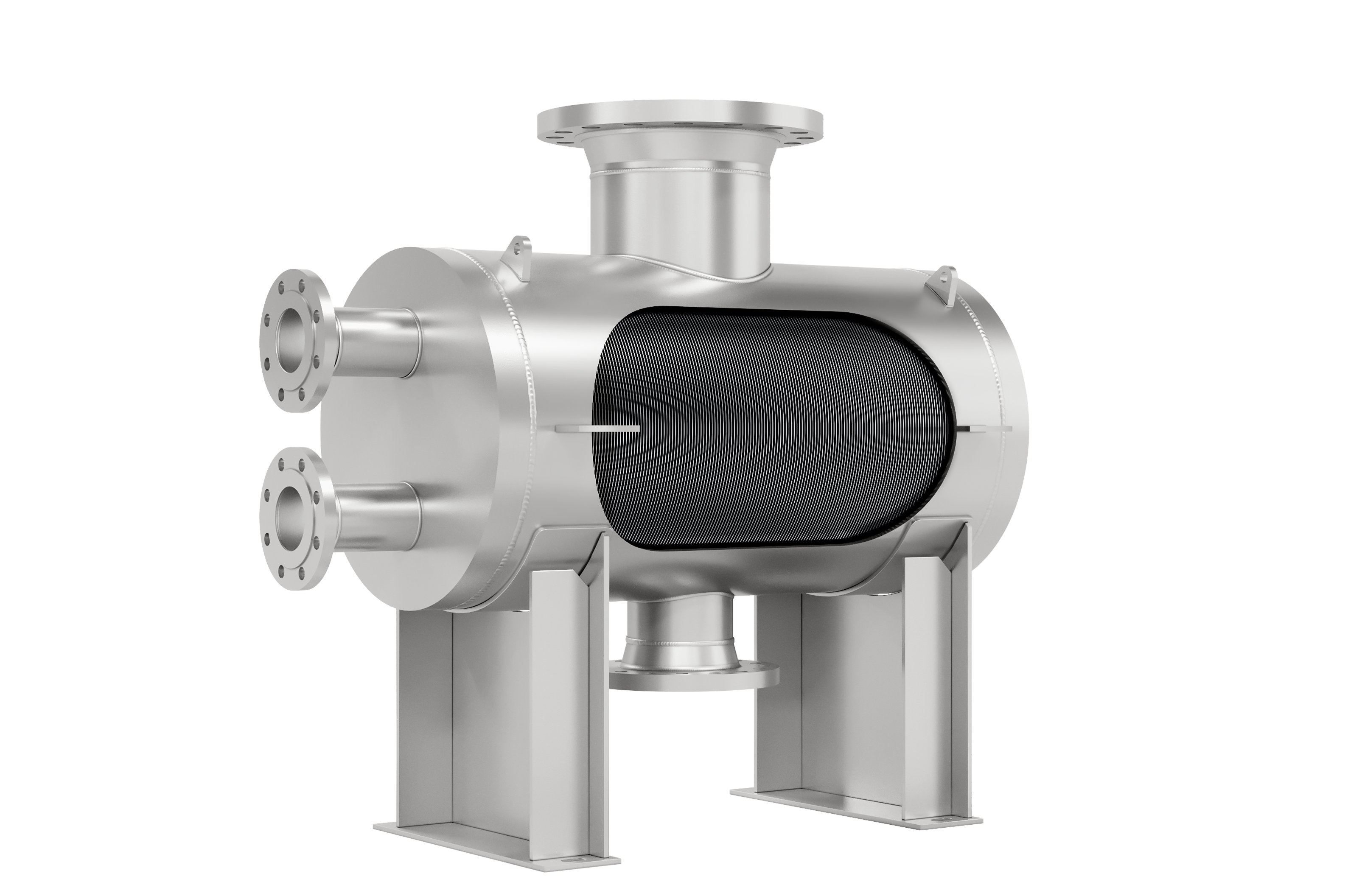

The SHIELD plate and shell heat exchanger represents a new, revolutionary solution, ensuring not only increased flow turbulence, but also extensive heat exchange area.

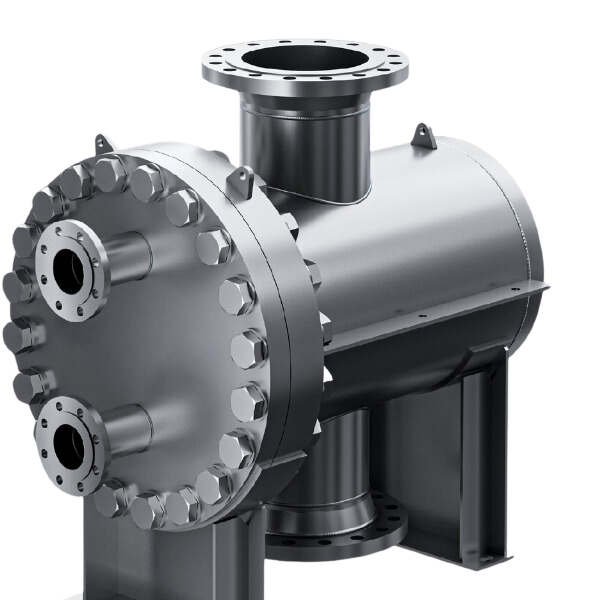

Plate and shell heat exchangers, as an alternative to shell and tube exchangers, are perfect for operating at high pressures and high temperatures. The design of the new SHIELD allows for a more compact, lighter, and, above all, more efficient exchanger, perfectly adaptable to individual requirements.

The “jagged” channel design creates more turbulent flow, which improves heat exchange and reduces sediment accumulation. An additional benefit is the extensive heat exchange area and reduced overall pressure drops. Highly efficient, SHIELD plate and shell heat exchangers provide a reliable solution for applications requiring high working pressures. They are perfect for the refrigeration industry, as well as for industrial cooling and heating systems. They are also ideal for economizers, gas heaters and coolers, CIP cleaning systems, and systems with aggressive media.

Features

-

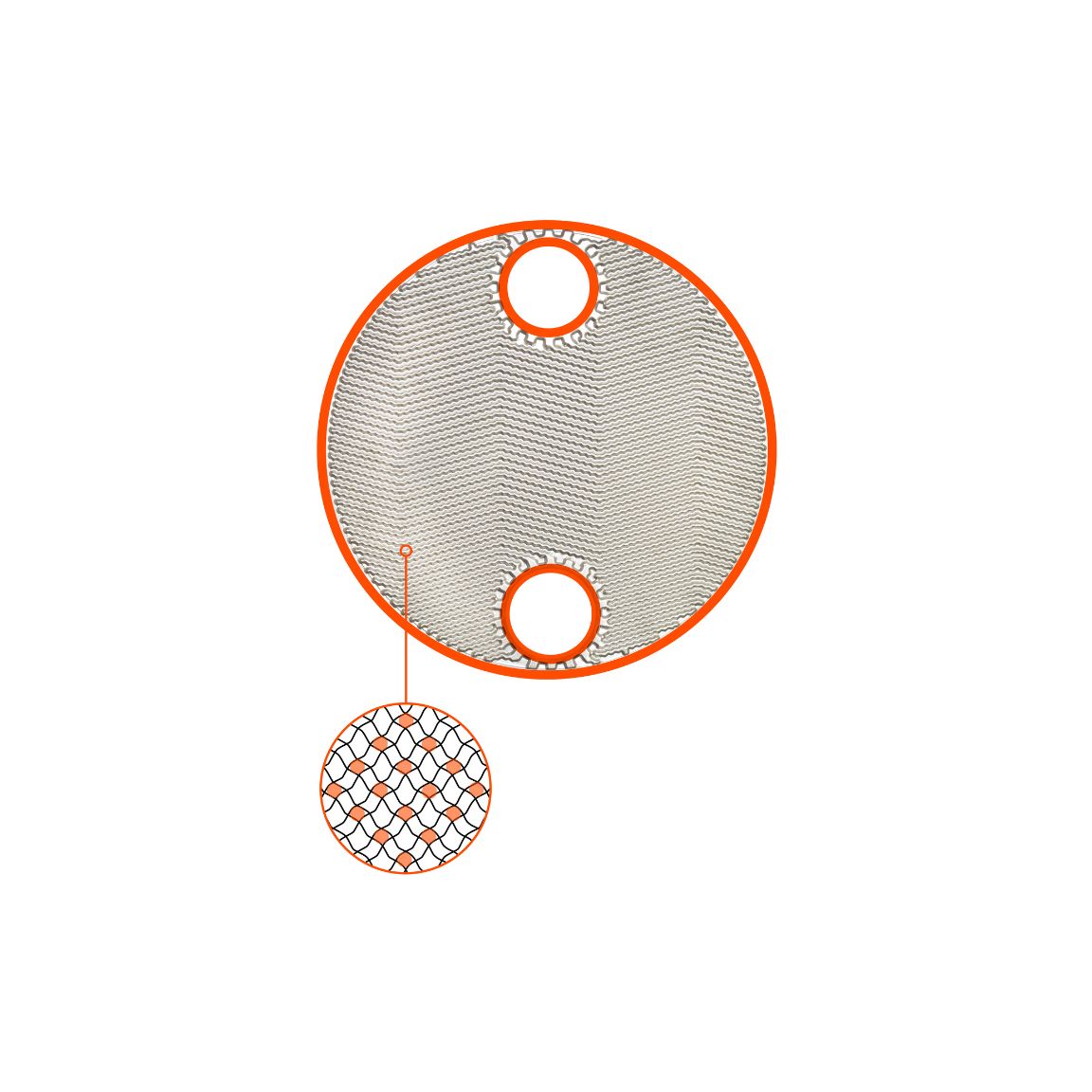

Innovative JAG heating plates corrugations patternincreases thermal effectiveness of the exchanger

-

Optimized utilization of the exchanger volumeallows to decrease its size

-

Durable Constructionprolongs equipment life, minimizing maintenance and downtime

-

Compact sizeallows for space savings

-

Available in various optionsmake the device adaptable to specific operational requirements and applications

Design

-

Shell

-

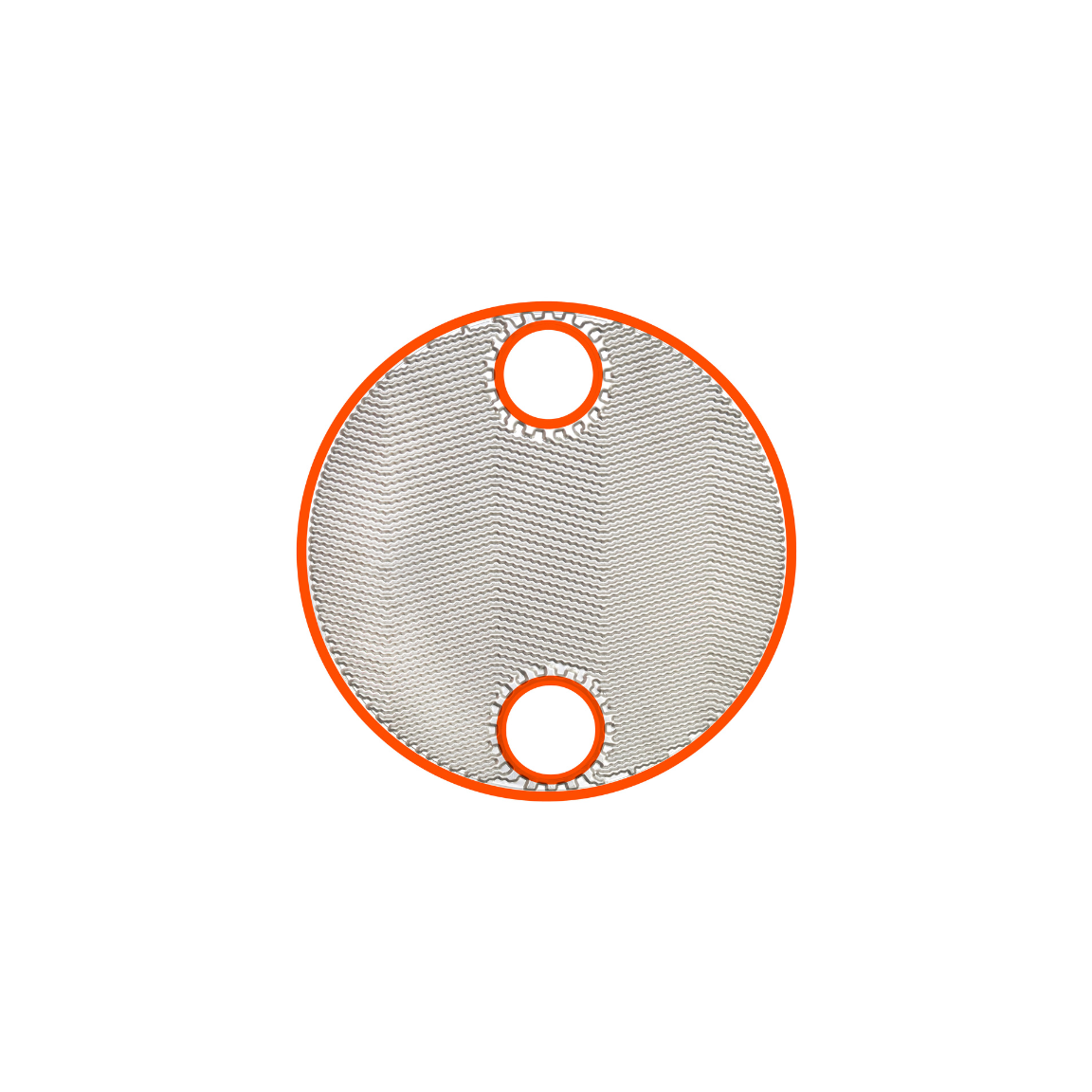

Heating plates pack

-

Plate side connections

-

Shell side connections

-

Mounts

-

Lifting lugs

REINFORCED PLATE CONSTRUCTION

A plate pack is enclosed in a solid structure. The plates are joined in pairs using the laser welding method, and the plate pack is created by a robotic TIG welding system, making the unit leak proof and resistant to variable loads and thermal stresses.

VACUUM BRAZING FOR ENHANCED STRENGTH AND RELIABILITY

Additionally, there is the option of using vacuum brazing as a supplementary method for joining and reinforcing the plates, which allows for a significantly larger contact surface and increases the device’s strength. All of the plates are joined along the entire outer surface, at the ports, and additionally at several optimally selected points in the heat exchange area.