The design and performance of JAD shell and tube heat exchangers make them perfect for the most demanding applications.

Their sizes, compact in relation to the heat exchange area, and consequently the high performance as compared to the standard solutions, are appreciated by many installers and users. Made entirely of stainless steel, they offer a durable and sturdy design.

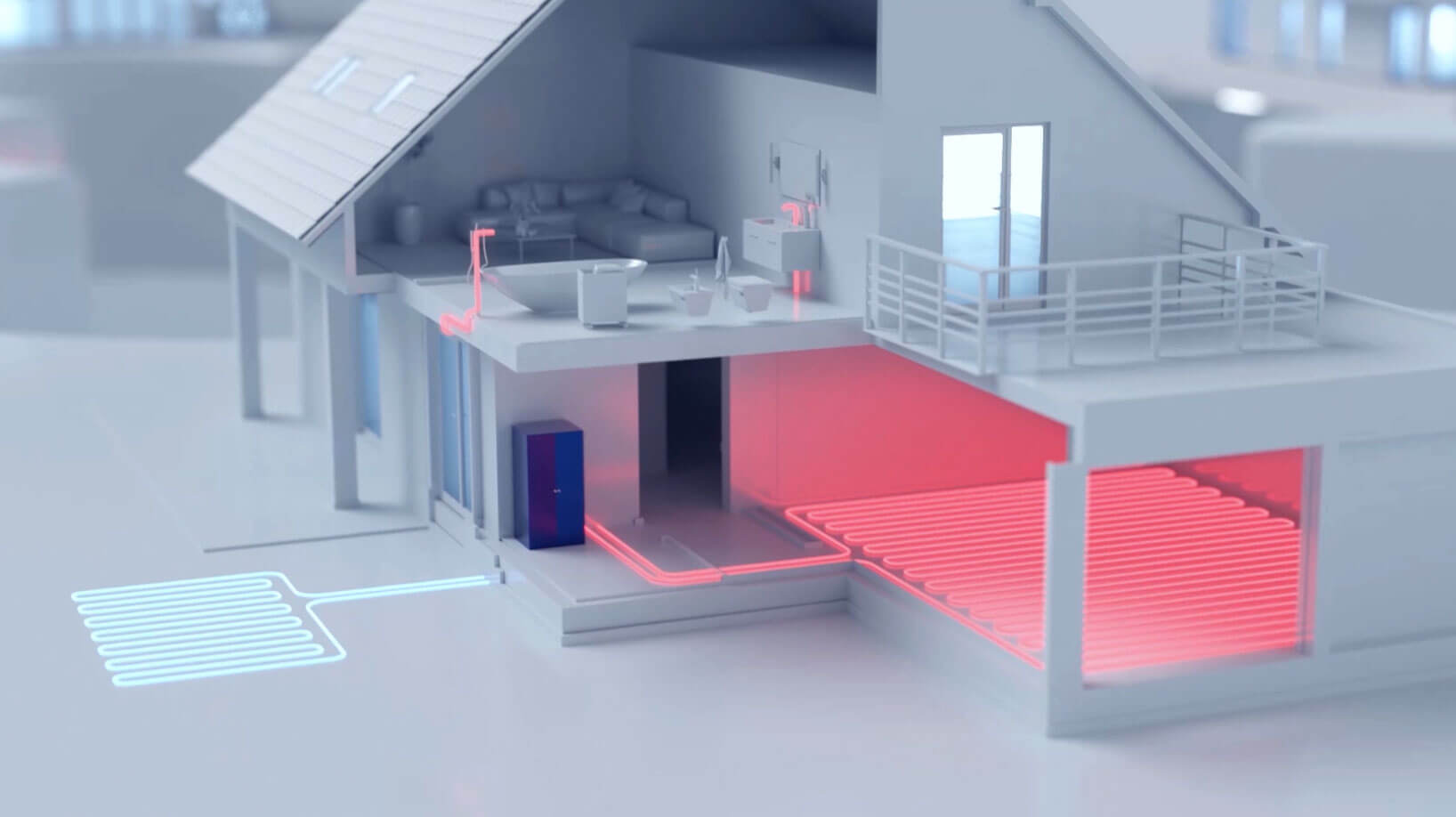

Due to their design flexibility, they may become a part of most heat transfer systems. Thanks to their properties, JAD exchangers are most often used in heating installations and heating substations, while JAD X – in installations with high requirements.

Features

- Saving space - compact size of the exchanger and the possibility of vertical installation reduce the space necessary for installation

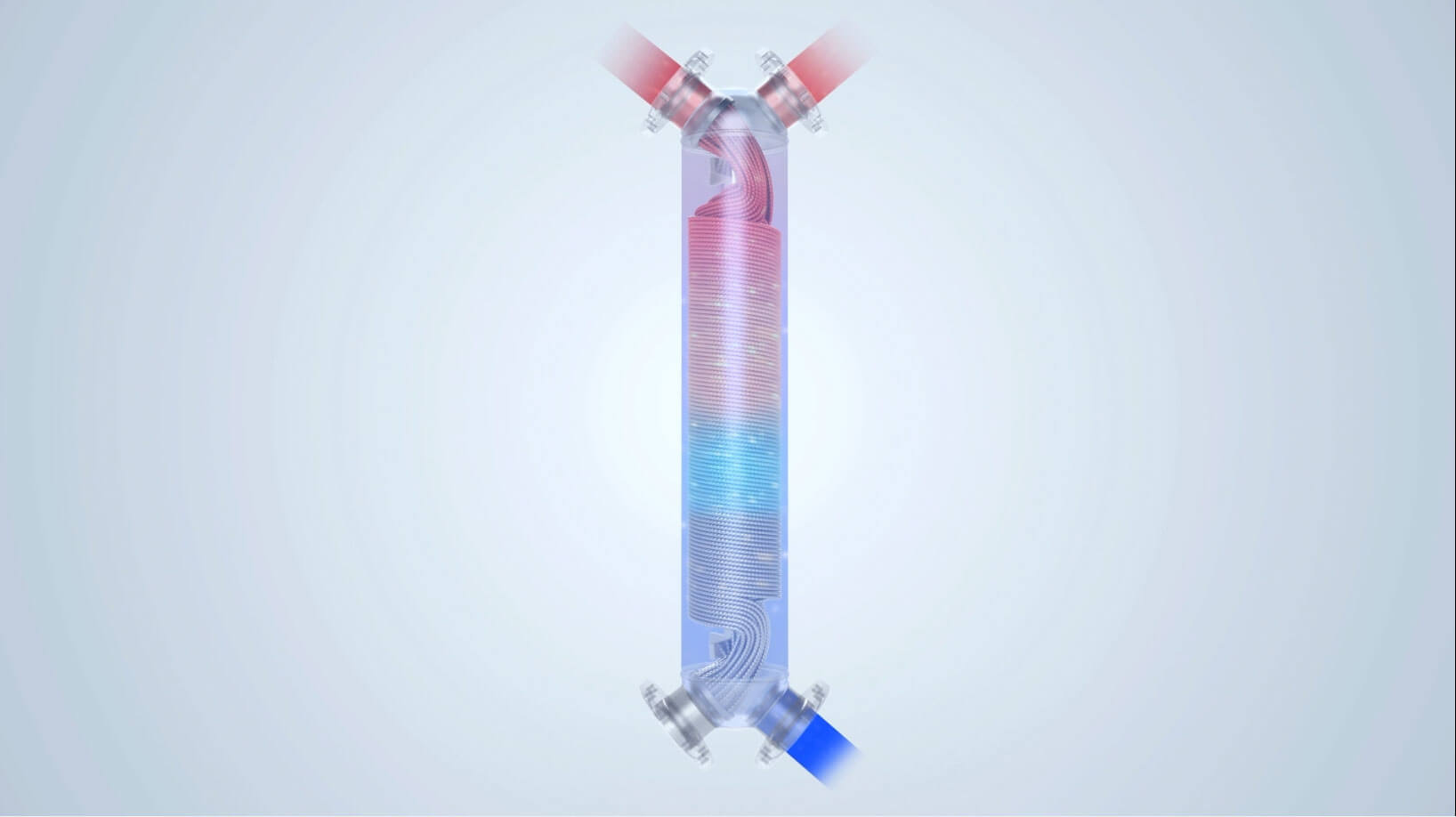

- Low operating costs - the X-shaped design of the connections and corrugated coil tubes make the exchangers more resistant to deposits

- High efficiency - higher heat exchange coefficient obtained thanks to corrugated tubes, which increase the flow turbulence, intensifying the heat exchange

- Broad range of applications - broad range of temperatures and pressures, flow speeds and the utilized media

- Made according to PED and ASME

- Various connection angles - 45˚ in JAD X and 90˚ in JAD

Corrugated tubes – turbulent flow

Higher heat exchange coefficient obtained thanks to corrugated tubes, which increase the flow turbulence, intensifying the heat exchange.

Smooth tubes

Smaller pressure drop, especially at high flows.

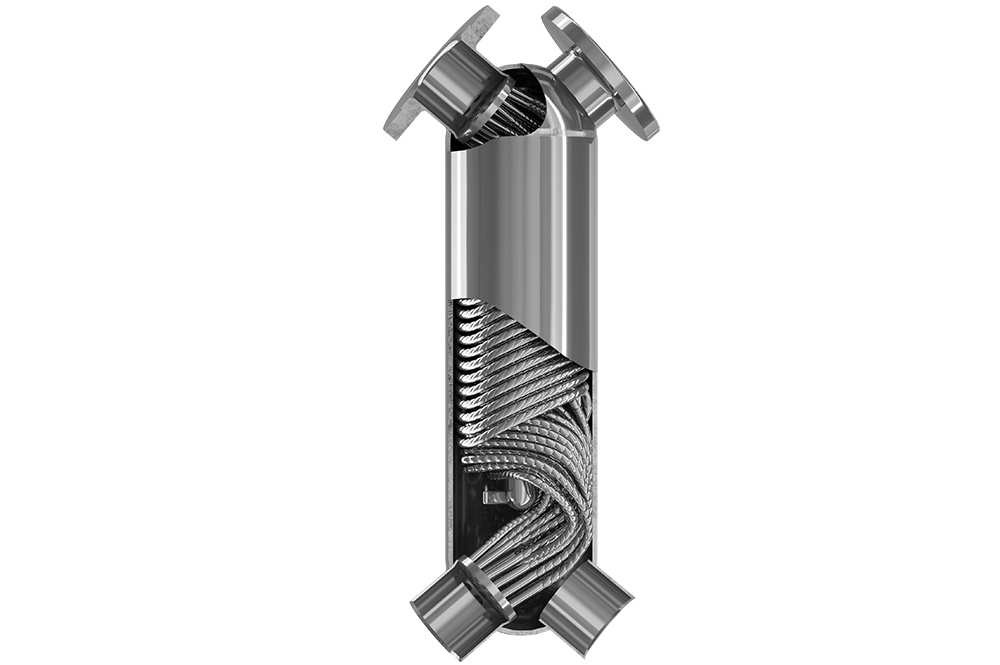

Design

-

Coil fitted with tubesheetsmade of counter-coiled tubes with external diameter of Ø 8 mm or Ø 10 mm

Coil fitted with tubesheetsmade of counter-coiled tubes with external diameter of Ø 8 mm or Ø 10 mm

-

Shell

-

Flanges

-

Dished heads

-

Core

Core

-

Connectionsfor welding, external thread or Victaulic