Supermarkets

Cooling systems are an indispensable part of installations in supermarkets. With the wide range of products offered in large format stores, many of them require storage under cooling or freezing conditions.

Cooling systems are an indispensable part of installations in supermarkets. With the wide range of products offered in large format stores, many of them require storage under cooling or freezing conditions.

First of all, investors should take into account the costs and the operating safety of the installation. In order to design a system, you need to determine the number and distribution of heat extraction points. The most essential points are cooling furniture, cooling chambers and air-condition installations.

Hexonic offers a number of heat exchangers that successfully operate in store cooling systems, ensuring safe and optimized system operation.

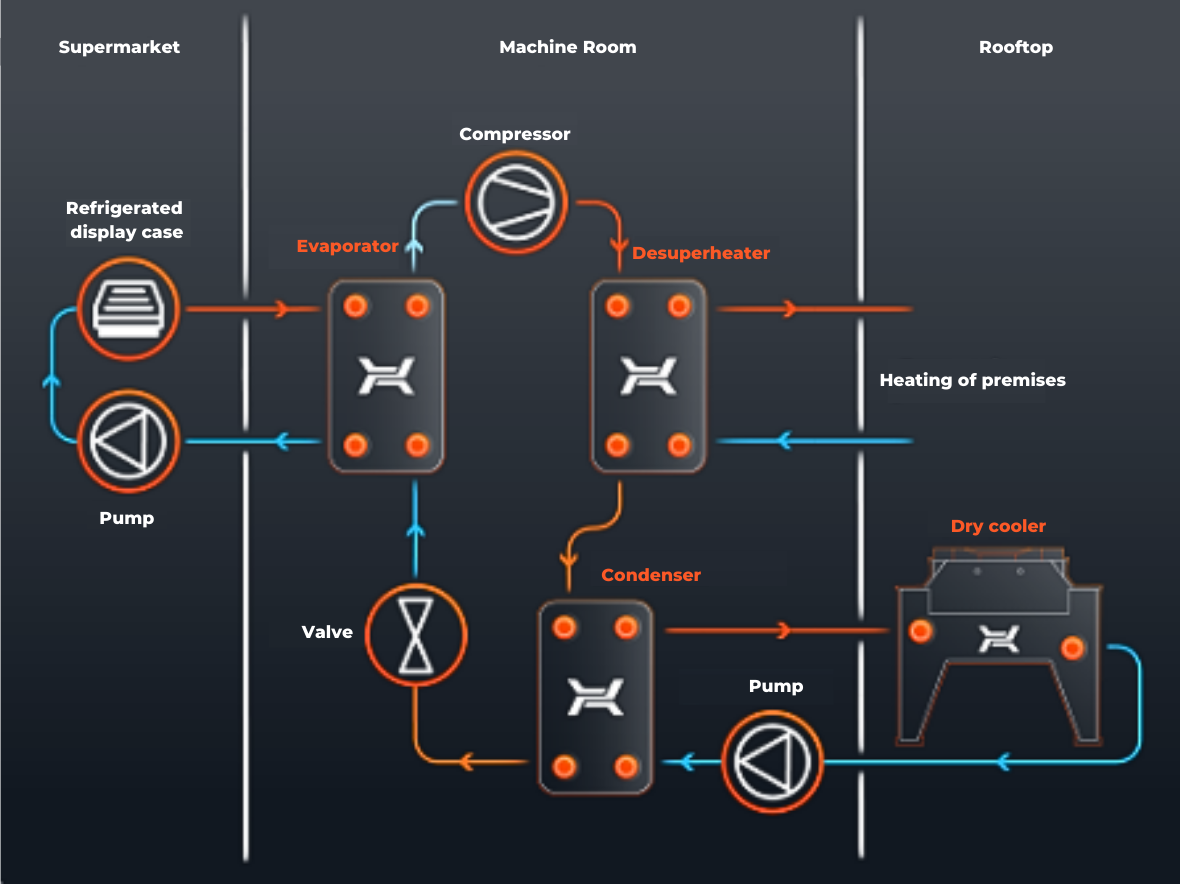

Indirect cooling systems are divided into two types of circuits – primary cooling medium circuit and one or two secondary circuits.

Indirect cooling systems with secondary liquid circuits are often composed of compact cooling units. The compressor, evaporator and condenser are located in the machinery room, far away from the counters where the process of cooling and heat recovery occurs. This system not only enables reducing primary cooling medium usage but also reduces the risk of its leakage. Thus it is possible to use ammonia as a cooling medium in store systems. They can be successfully used in the primary circuit, which is located in a safe and sealed room.

Using Hexonic brazed plate exchangers as condensers, evaporators and desuperheaters ensures performance and safety of the cooling system located in the machinery room.

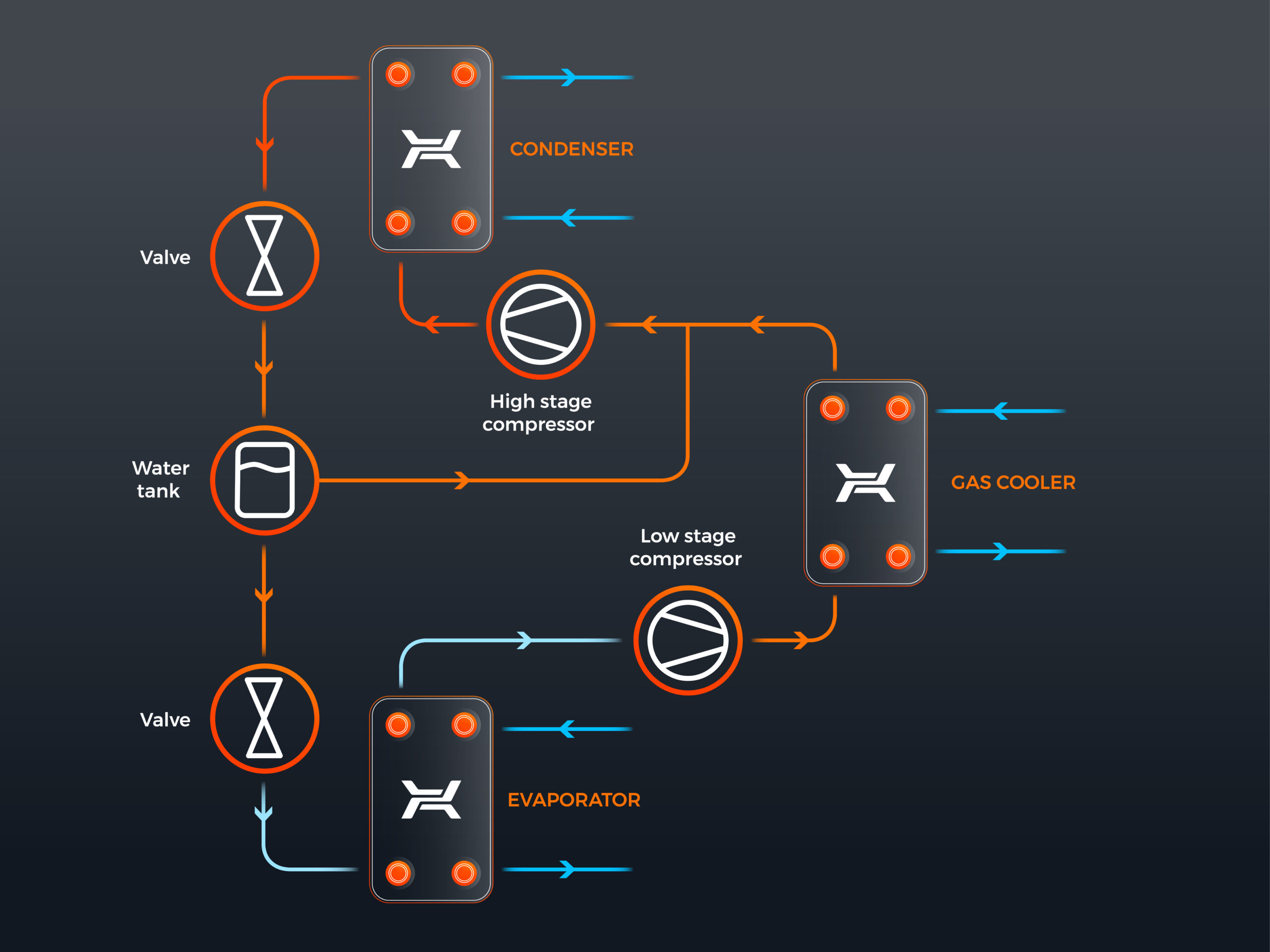

The low-temperature evaporation process requires low pressure, whereas the condensation pressure is at a normal level. In some cases it is necessary to separate the stages of evaporation and condensation pressures with more than one compressor stage. This is due to the fact that as the pressure ratio in the compressor increases, temperature at the compressor output will also rise. Operation in high temperatures affects the life span and performance of compressors, thus increasing operation costs.

For generating particularly low temperatures, cooling systems with two stage compression are used. In ultra-low temperatures, big pressure differences between the evaporator and the condenser are required. The performance by volume of compressors is significantly lower with high pressure ratios. Intercooling with gas is used between the two compressors stages.

Interstage cooling of cooling medium vapors between the low stage and the high stage compressor helps reduce the outlet temperature of the high stage compressor to harmless values, improving the compression performance and reducing energy consumption.

A two stage system operates with two stage compression. The expanding gas is separated from the liquid cooling medium between two expansion valves and is routed to the high stage compressor. Removing the gas between the expansion stages lowers the quality of cooling medium vapors at the evaporator inlet. Due to the lower quality of the vapor at the inlet, the cooling medium passing through the evaporator will be able to absorb more heat, reducing the required mass flow of the cooling medium for given cooling performance. As a result, the dimensions of the low stage compressor may be smaller, and due to the increased heat transfer coefficient in the evaporator, also the required heat exchange surface is reduced.

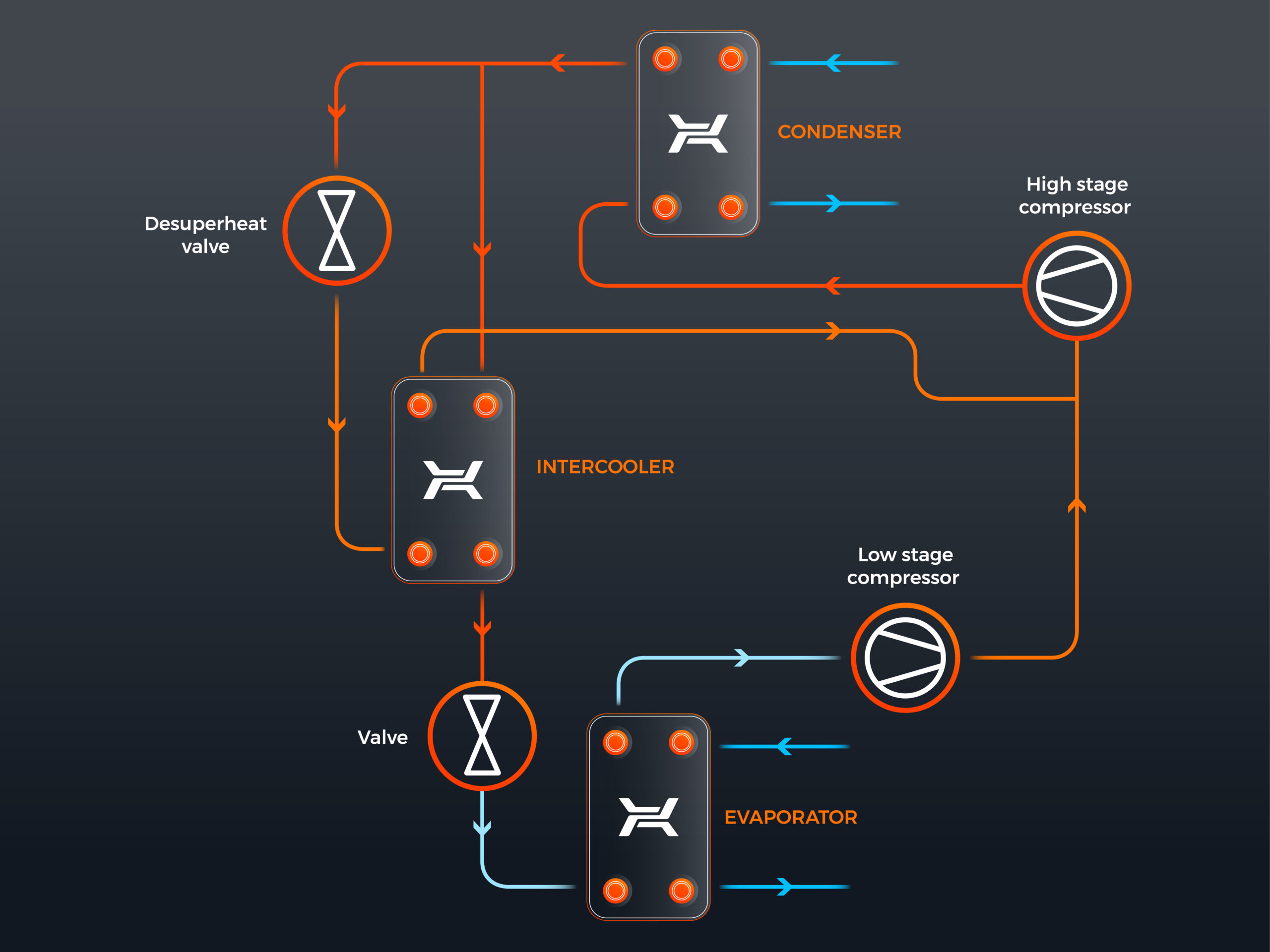

A system fitted with an intercooler uses the intermediary evaporation stage for cooling the outlet gas from the first stage compressor. The subcooling process reduces the inlet vapor quality, thus reducing the cooling medium flow rate through the evaporator. The system may then include a smaller low stage compressor to achieve the required cooling efficiency. After leaving the intercooler, the cooling medium is not completely evaporated. The remaining liquid is evaporated after mixing with hot outlet gas from the low stage compressor. This results in a more efficient gas cooling. High stage compressor outlet gas temperature may be kept within acceptable limits, thus additionally increasing compressor performance.

The Hexonic brazed plate heat exchanger minimizes the temperature difference between the evaporating and the cooled stream, increasing system performance.

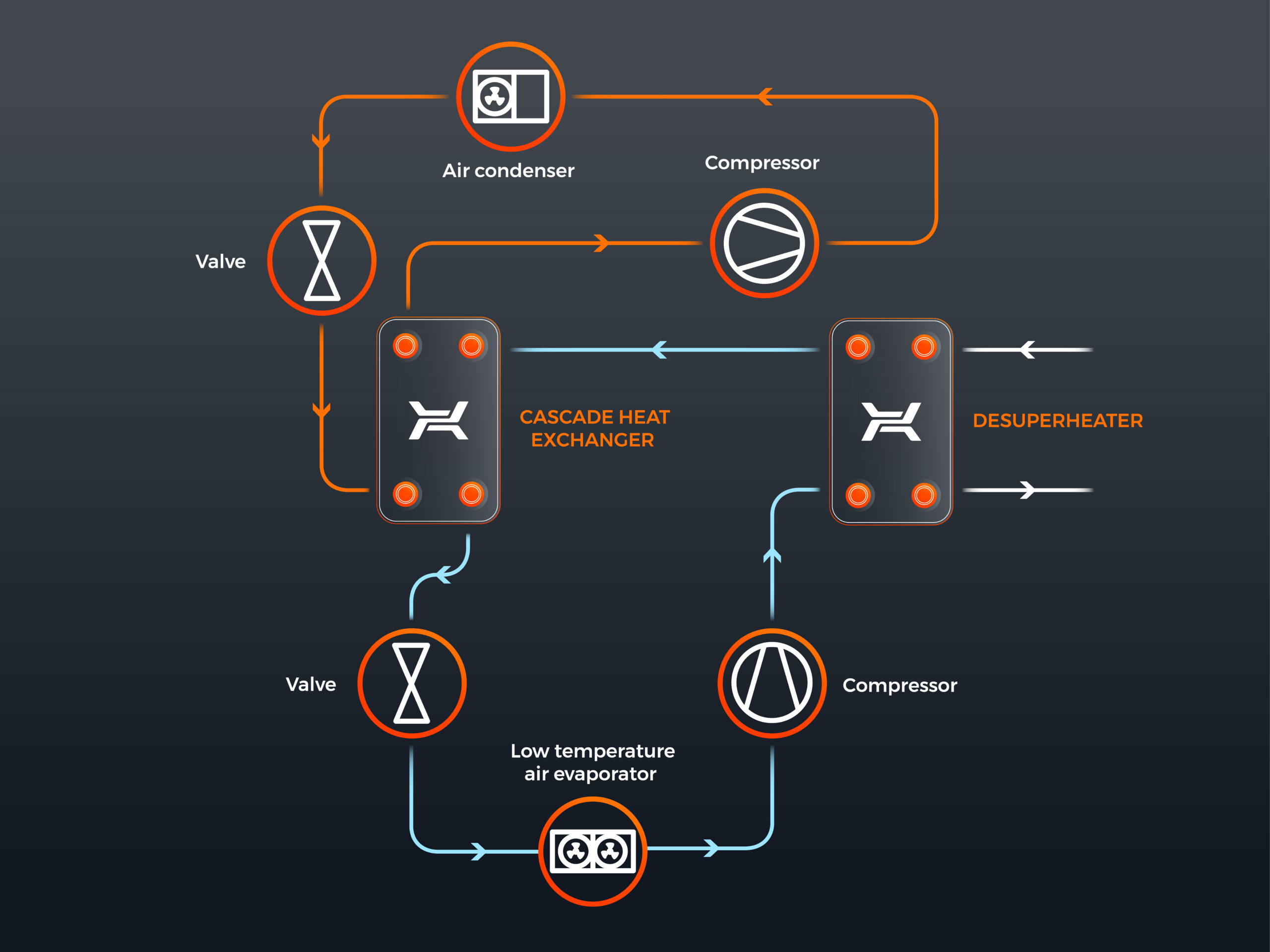

A cascade system consists of two separate cooling circuits, where the cooling medium appropriate for a specific temperature range is used. Both circuits are connected with one another through an intermediary cascade heat exchanger, serving as a condenser and an evaporator.

The high temperature circuit is cooled by the air condenser and uses a cascade heat exchanger as an evaporator, while the low temperature circuit is responsible for cooling the cold evaporator, using it as a condenser. The advantage of the system is the possibility to use two types of cooling media with different vapor pressures, and the selection of an appropriate cooling medium and the distribution of oil in the cascade system may be discussed separately for each circuit.

A brazed plate heat exchanger will constitute the perfect cascade heat exchanger due to its resistance to temperature changes and pressure surges. Regarding very high temperature differences which have a negative impact on the heat exchanger as such, it is recommended to install the desuperheater upstream the outlet on the condensing side. The desuperheater reduces the outlet gas temperature on the cascade unit side, using the overheating energy to generate high temperature water.

More and more frequently current trends lead to environment friendly solutions. CO2-based cooling systems are becoming more and more popular. In order to optimize CO2-based cooling systems, two stage compressor cascades are usually used, where the upper stage features circuits with higher critical temperature working medium.