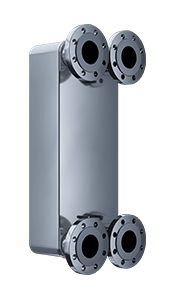

Brazed plate heat exchangers are the perfect solution that allows for maintaining high thermal performance at low operating costs.

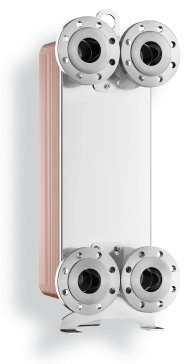

The L series brazed plate heat exchangers are a perfect solution for heating and cooling installations. Permanently connecting heating plates during the brazing process in the vacuum furnace guarantees reliable operation at low operating costs. Extensive heat exchange area allows for highly efficient operation in demanding conditions.

Wide range of types, sizes, and numbers of plates and connections allows for optimizing the selection to particular application. Copper or stainless brazing and the double wall option offer additional application possibilities. Brazed exchangers guarantee reliable, long-term operation.

Features

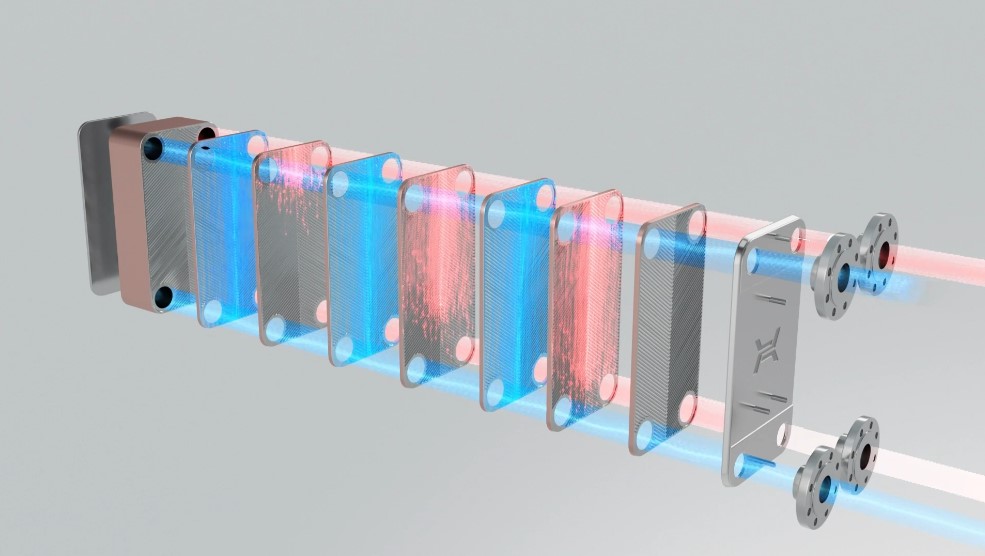

- Turbulent flow thanks to the special corrugation pattern of the heating plates

- Airtight design - permanent connection of the plates during the vacuum brazing process, using the copper or stainless LUNATM brazing.

- Low operating costs – competitive exchanger price and long-term maintenance-free operating period

- Saving space – extensive heat exchange area in small exchanger dimensions

- Reliable - adapted to operate in demanding conditions of temperature and pressure differences

- Optimized for any use – thanks to the single- and double-flow versions, wide range of connections and the selection of proper number of plates.

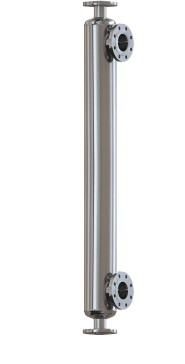

High efficiency compared to shell and tube heat exchangers

lower height of the exchanger, with the same heat exchange area

more performance, with the same heat exchange area

higher value of the heat exchange coefficient

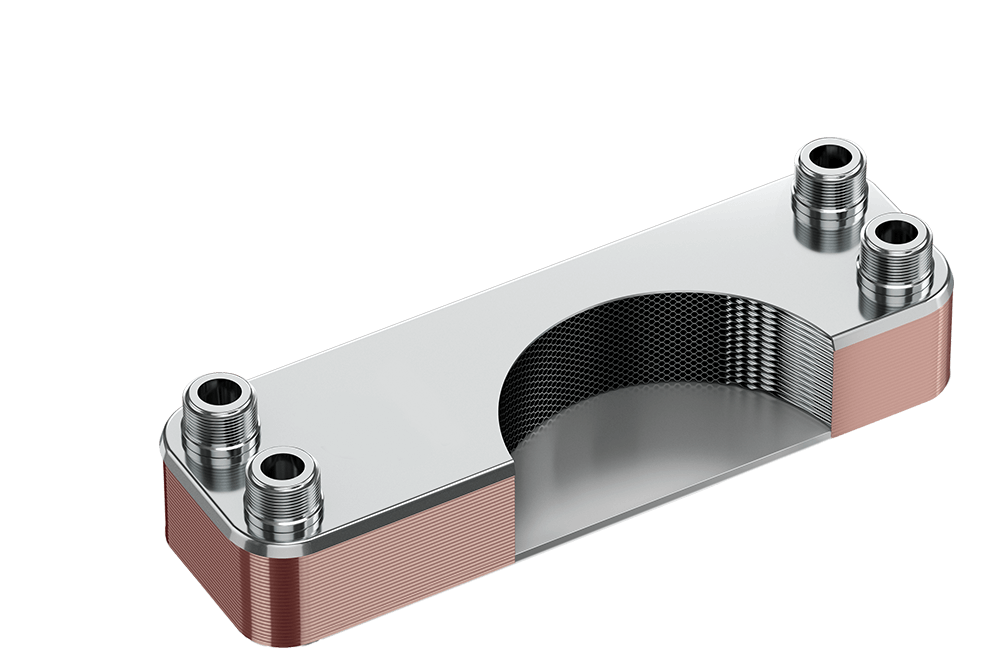

Design

-

Copper or stainless LUNATM brazing

-

Connections

-

Heating plates

-

Cover plates

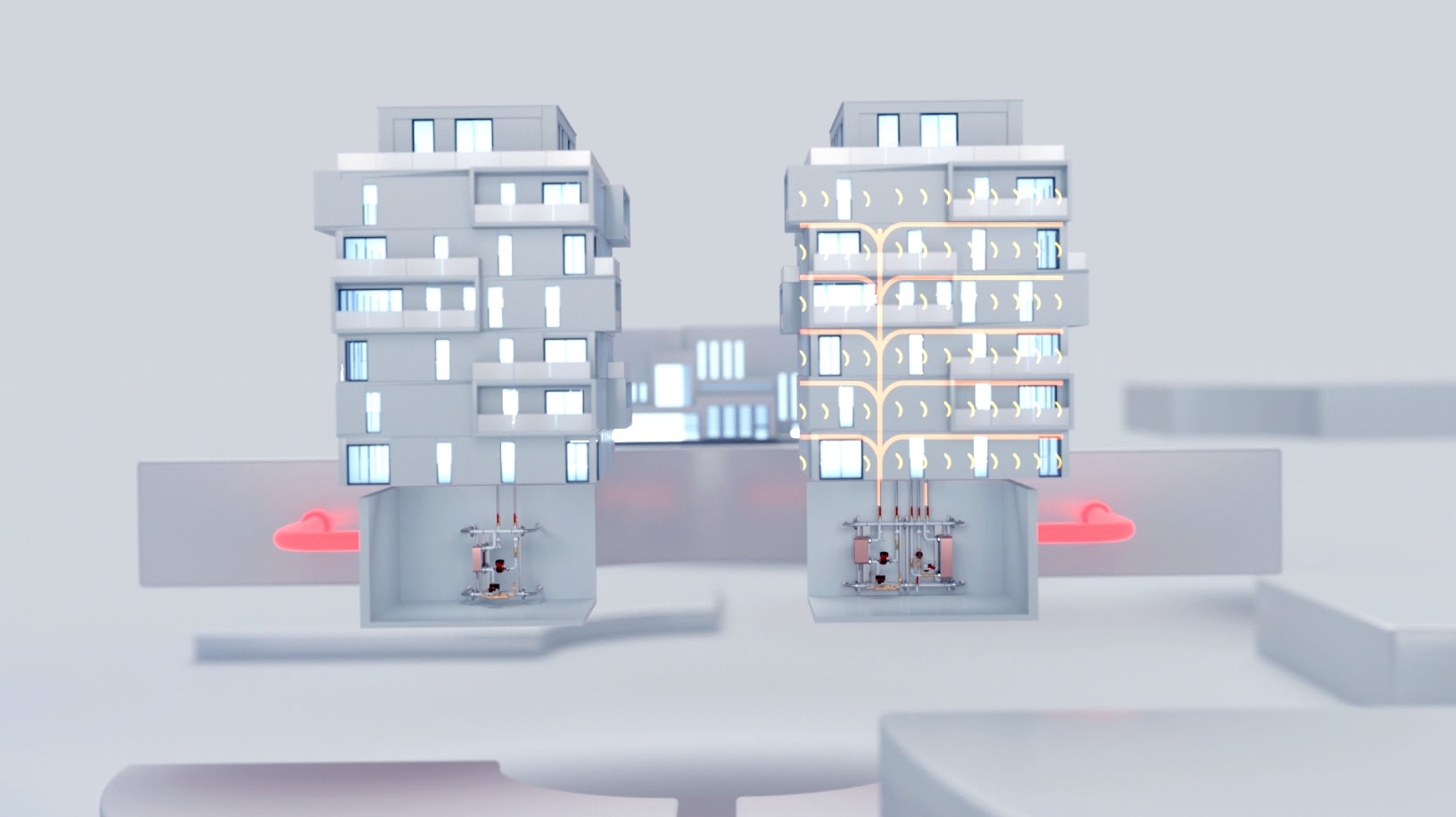

How does the brazed plate heat exchanger work?

Brazed plate heat exchangers in heating systems