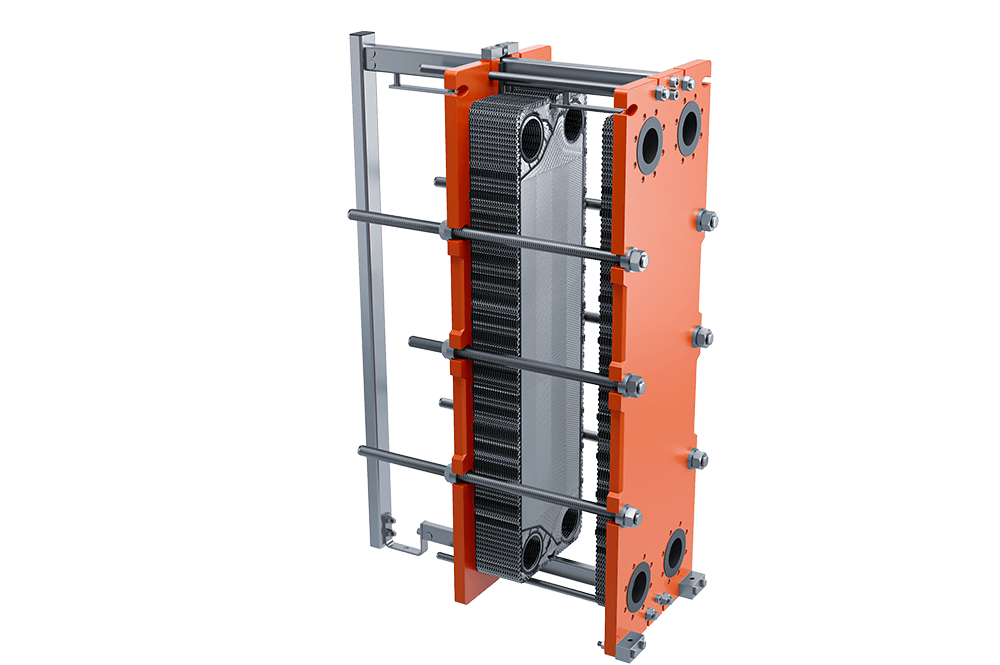

JAG F plate and frame heat exchangers are a new, revolutionary solution, ensuring not only increased flow turbulence, but also extensive heat exchange surface.

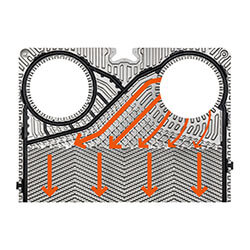

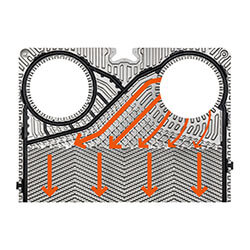

The innovative JAG heating plate corrugation pattern, developed through extensive product research, enables a more compact, lighter, and, above all, more efficient exchanger, perfectly tailored to individual requirements. The new “jagged” channel design increases flow turbulence, which improves heat exchange and also decreases sediment accumulation.

The additional benefit is an extensive heat exchange surface and decreased overall pressure drops. JAG F plate heat exchanger also features a range of technical solutions for the frame construction that make the highly efficient JAG F plate heat exchanger a reliable solution in many applications.

Features

- High thermal performance thanks to innovative heating plate corrugations pattern

- Technical solutions facilitating the exchanger installation and operation

- Option to adjust the exchanger design to the required installation operating parameters by selecting proper number and size of the heating plates

- Heating plates made of stainless steel or titanium to be used in aggressive media systems or pools with salt water

- Dismountable design – allows for cleaning and extension, if necessary

- Wide range of products

- Made of stainless steel (optional)

- The available double-wall system option helps prevent media mixing and enables quick leak detection in critical installations.

Design

-

Metal rollerin larger models – allows for easy sliding of rear plate, decreasing time and effort of maintenance. The rollers are equipped with Teflon or polyamide slides that stabilize the rear plate

Metal rollerin larger models – allows for easy sliding of rear plate, decreasing time and effort of maintenance. The rollers are equipped with Teflon or polyamide slides that stabilize the rear plate

-

U-legFacilitates plate pack installation. It is also intended for mounting the heat exchanger to the mounting platform

U-legFacilitates plate pack installation. It is also intended for mounting the heat exchanger to the mounting platform

-

Additional front feetstabilize the heat exchanger and facilitate its firm mounting to the mounting platform

Additional front feetstabilize the heat exchanger and facilitate its firm mounting to the mounting platform

-

Special carrying bar profileIntended for suspending heater plates in larger models. It is also intended for proper plate positioning. It is part of the five point mounting system

Special carrying bar profileIntended for suspending heater plates in larger models. It is also intended for proper plate positioning. It is part of the five point mounting system

-

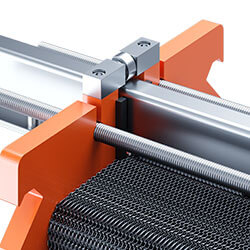

Lock washerfacilitates and speeds up unscrewing of the tightening bolts

Lock washerfacilitates and speeds up unscrewing of the tightening bolts

-

Front and rear cover platemade of painted carbon steel, different colors available on demand

-

Connections size: DN32 to DN350

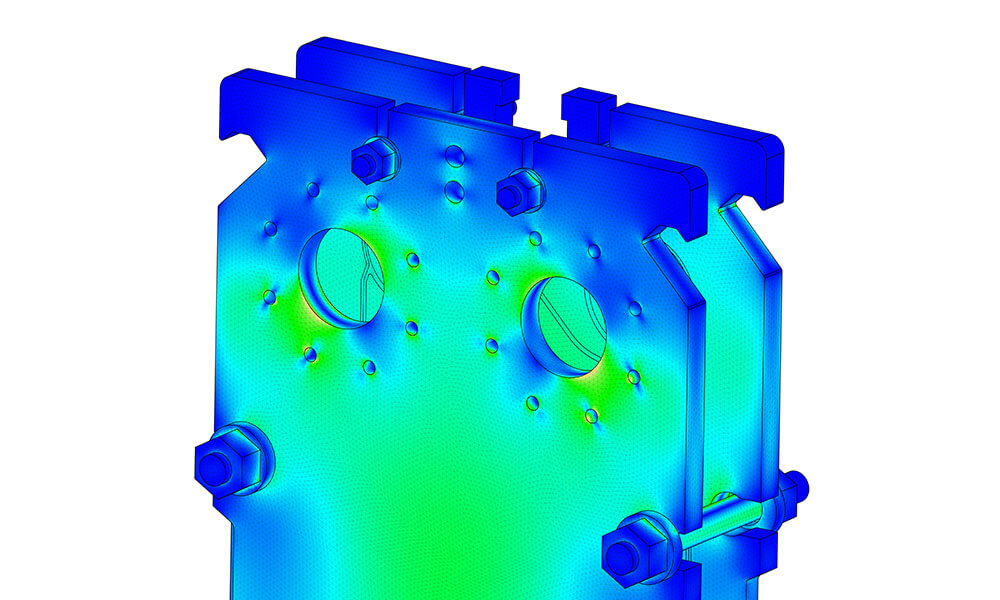

Finite element method

The application of the Finite Element Method (FEM Analysis) was intended to optimize the design in terms of durability, mainly by improving the stress distribution on cover plates and modifying fasteners, which led to expanding the scope of working parameters of the device.

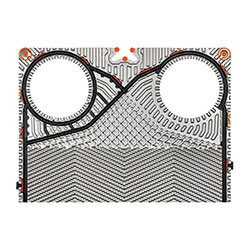

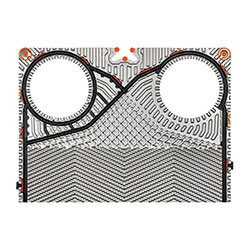

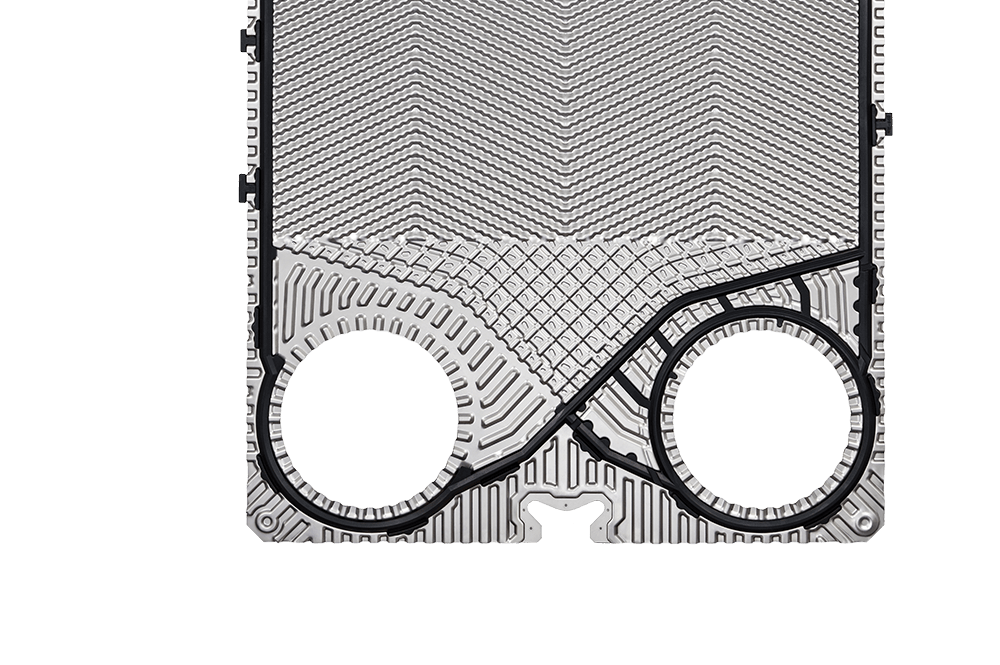

JAG PLATE – reinvented

-

Innovative JAG corrugations pattern

Innovative JAG corrugations pattern

-

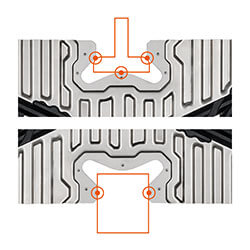

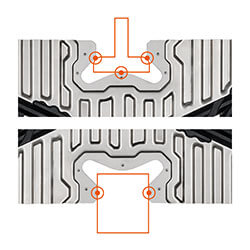

Triple heater plates positioning system

Triple heater plates positioning system

-

Modified distribution area

Modified distribution area

-

Optimized sealing surface

Optimized sealing surface

-

Additional plate reinforcement

Additional plate reinforcement

-

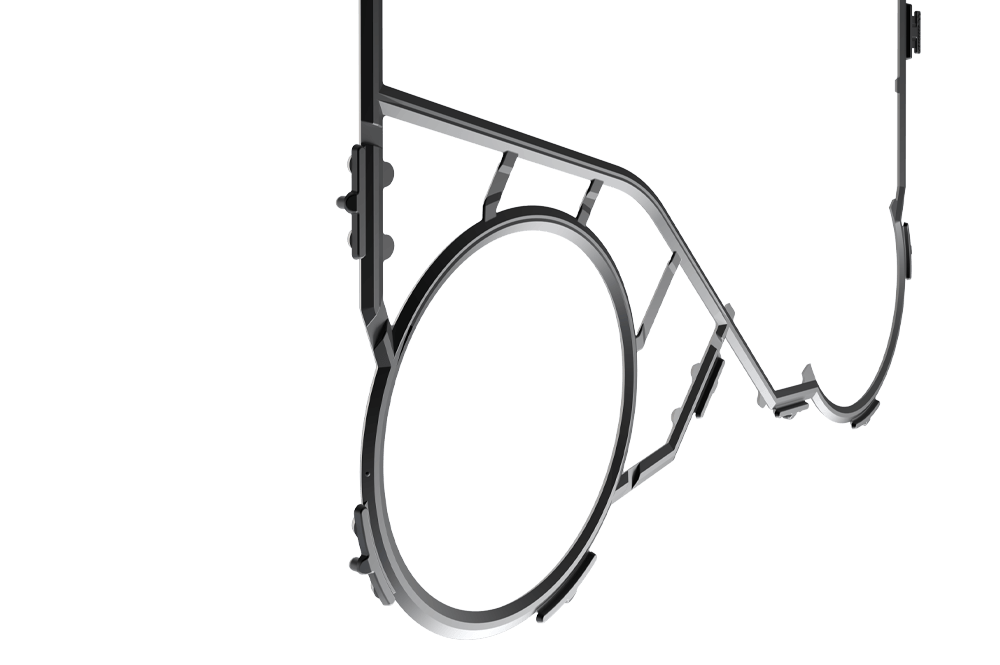

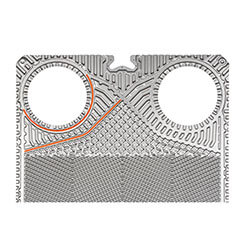

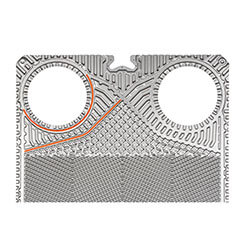

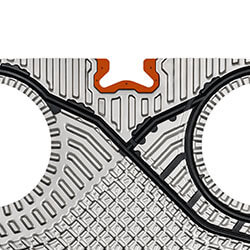

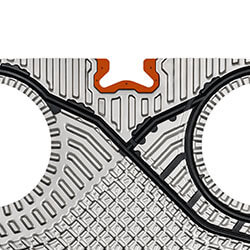

Patented hybrid gasket mounting systemthe new patented gasket features two mounting methods and optimized, unique shape

Patented hybrid gasket mounting systemthe new patented gasket features two mounting methods and optimized, unique shape

-

Five point mounting system

Five point mounting system

-

32–250 mm ports

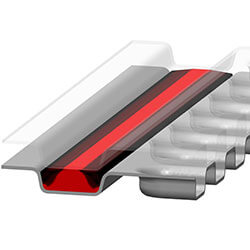

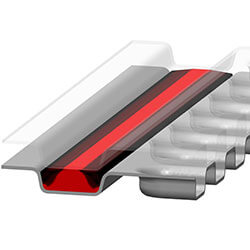

Gasket design

-

Lock-in method- specially designed bolts are pressed into the corresponding cut-outs in the heating plate. The lock-in locks stabilize the gasket on the plate during installation

Lock-in method- specially designed bolts are pressed into the corresponding cut-outs in the heating plate. The lock-in locks stabilize the gasket on the plate during installation

-

Lock-on method- a T-shaped attachment grips the proper fragment of the profiled edge of the heating plate, mounting the gasket to the vertical side of the plate. This facilitates and speeds up the installation process

Lock-on method- a T-shaped attachment grips the proper fragment of the profiled edge of the heating plate, mounting the gasket to the vertical side of the plate. This facilitates and speeds up the installation process

-

Optimized, unique shape of the gasketensures perfect sealing, even in high pressure applications

Optimized, unique shape of the gasketensures perfect sealing, even in high pressure applications

-

Highest production standardshigh quality materials and reliable deliveries